Note:

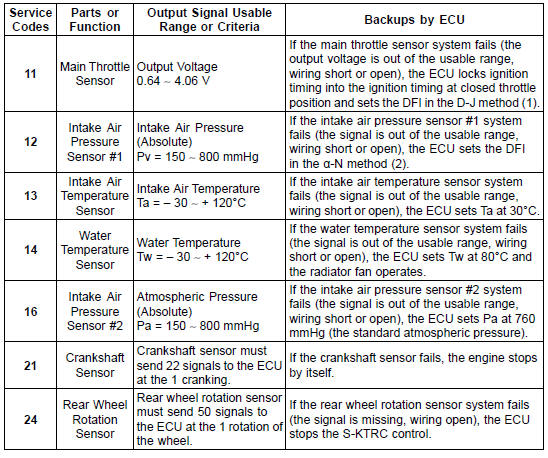

(1): D-J Method: When the engine load is light like at idling or low speed, the ECU determines the injection quantity by calculating from the throttle vacuum (vacuum sensor output voltage) and engine speed (crankshaft sensor output voltage). This method is called D-J method.

(2): α-N Method: As the engine speed increases, and the engine load turns middle to heavy, the ECU determines the injection quantity by calculating from the throttle opening (throttle sensor output voltage) and the engine speed. This method is called α-N method.

*: This depends on the number of stopped cylinders.

The main throttle sensor is a rotating variable resistor that change output voltage according to throttle operating. The ECU senses this voltage change and determines fuel injection quantity, and ignition timing according to engine rpm, and throttle opening.

Input Terminal [A]: BL Output Terminal [B]: V/W Ground Terminal [C]: BR/BK

Service Code Erasing

Service Code ErasingSelf-Diagnosis Procedures

NOTE

Use a fully charged battery when conducting

self-diagnosis. Otherwise, the light (LED) and symbol

do not light or blink.

Turn the ignition switch to ON.

When a problem occurs with DFI system and ignition system,

the warning indicator light (LED) [A] goes on and

FI warning symbol ...

Crankshaft Main Bearing

Insert/Journal Wear Inspection

Split the crankcase (see Crankcase Splitting).

Cut strips of plastigage to journal width.

Place a strip on each journal parallel to the crankshaft

installed in the correct position.

Tighten the crankcase bolts to the specified torque (see

Crankcase Assembly).

NOTE

Do not turn ...

Shift Pedal Removal

Remove:

Shift Lever Bolt [A]

Front Footpeg Bracket Bolts [B]

If the tie-rod [C] is to be removed from the shift pedal and

the shift lever, loosen the tie-rod locknuts [D].

The front tie-rod locknut is left-hand thread.

Remove:

Shift Pedal Mounting Bolt [A]

...