NOTE

Do not move the connecting rod and crankshaft during clearance measurement.

Remove the connecting rod big end again, measure each clearance between the bearing insert and crankpin [A] using plastigage (press gauge) [B].

NOTICE

After measurement, replace the connecting rod bolts and nuts.

Connecting Rod Big End Bearing Insert/Crankpin Clearance

Standard: 0.030  0.060 mm

0.060 mm

(0.0012  0.0024 in.)

0.0024 in.)

Service Limit: 0.10 mm (0.0039 in.)

If the clearance is within the standard, no bearing replacement is required.

If the clearance is between 0.061 mm (0.0024 in.) and the service limit (0.10 mm, 0.0039 in.), replace the bearing inserts [A] with inserts painted blue [B]. Check insert/ crankpin clearance with the plastigage. The clearance may exceed the standard slightly, but it must not be less than the minimum in order to avoid bearing seizure.

If the clearance exceeds the service limit, measure the diameter of the crankpins.

Crankpin Diameter

Standard: 34.484  34.500 mm

34.500 mm

(1.3576  1.3583 in.)

1.3583 in.)

Service Limit: 34.47 mm (1.3571 in.)

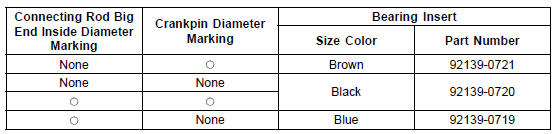

Crankpin Diameter Marks

None 34.484  34.492 mm (1.3576

34.492 mm (1.3576

1.3580 in.)

34.493

34.493

34.500 mm (1.3580

34.500 mm (1.3580

1.3583 in.)

1.3583 in.)

: Crankpin Diameter Marks (“” or

: Crankpin Diameter Marks (“” or

No Mark)

NOTE

The mark already on the big end should almost coincide with the measurement.

Connecting Rod Big End Inside Diameter Marks

None 37.500  37.508 mm

37.508 mm

(1.4764  1.4767 in.)

1.4767 in.)

37.509

37.509

37.516 mm (1.4767

37.516 mm (1.4767

1.4770 in.)

1.4770 in.)

Big End Cap [A] Connecting Rod [B] Weight Mark, Alphabet [C] Diameter Mark [D] (“” or No Mark)

Size Color [B]

Connecting Rod Big End Side Clearance Inspection

Connecting Rod Big End Side Clearance Inspection Crankshaft Side Clearance Inspection

Crankshaft Side Clearance InspectionTail/Brake Light (LED) Removal/Installation

Remove:

Upper Seat Cover (see Seat Cover Removal in the

Frame chapter)

Disconnect the tail/brake light connector [A].

Remove:

Tail/Brake Light Mounting Screws [A]

Bolts [B] and Brackets [C]

Bolt [D]

Remove the tail/brake light [A].

Bring down the rear fender rea ...

Dimmer Switch

High or low beam can be selected

with the dimmer switch. When the

headlight is on high beam ( ), the

high beam indicator light goes on.

High beam.......( )

Low beam.......( )

NOTE

When the headlight is on high beam,

both headlights go on. When the

headlight is on low beam, only one

headl ...

Front Master Cylinder Installation

Apply silicone grease to the sliding surface of the brake

lever pivot bolt.

Tighten:

Torque - Brake Lever Pivot Bolt: 1.2 N·m (0.12 kgf·m, 11

in·lb)

Brake Lever Pivot Bolt Nut: 5.9 N·m (0.60 kgf·m,

52 in·lb)

Assemble the reservoir [A] and the bracket [B] as shown

in the figu ...