As the tire tread wears down, the tire becomes more susceptible to puncture and failure. An accepted estimate is that 90% of all tire failures occur during the last 10% of tread life (90% worn).

So it is false economy and unsafe to use the tires until they are bald

A. Tire Depth Gauge

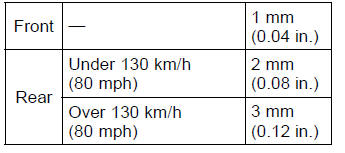

Minimum Tread Depth

NOTE

Have the wheel balance inspected whenever a new tire is installed.

| WARNING Tires that have been punctured and repaired do not have the same capabilities as undamaged tires and can suddenly fail, causing an accident resulting in serious injury or death. Replace damaged tires as soon as possible. To ensure safe handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure. If it is necessary to ride on a repaired tire, do not exceed 100 km/h (60 mph) until the tire is replaced. |

NOTE

When operating on public roadways, keep maximum speed under traffic law limits.

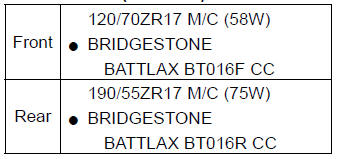

Standard Tire (Tubeless)

| WARNING Some replacement tires may adversely affect handling and cause an accident resulting in serious injury or death. To ensure proper handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure. New tires are slippery and may cause loss of control and injury. A break-in period of 160 km (100 miles) is necessary to establish normal tire traction. During break-in, avoid sudden and maximum braking and acceleration, and hard cornering. |

Payload and Tire Pressure

Payload and Tire Pressure Battery

BatteryBolts, Nuts and Fasteners Tightness Inspection

Check the tightness of the bolts and nuts listed here. Also,

check to see that each cotter pin is in place and in good

condition.

NOTE

For the engine fasteners, check the tightness of them

when the engine is cold (at room temperature).

If there are loose fasteners, retighten them to ...

Connecting Rod Installation

NOTICE

To minimize vibration, the connecting rods should

have the same weight mark.

Big End Cap [A]

Connecting Rod [B]

Weight Mark, Alphabet [C]

Diameter Mark [D] (“” or No Mark)

NOTICE

If the connecting rods, big end bearing inserts, or

crankshaft are replaced with new ones, select ...

Front Wheel Rotation Sensor Signal (Service Code 27)

Front Wheel Rotation Sensor Signal Inspection

The front wheel rotation sensor sends the signal to the

ECU through the KIBS hydraulic unit (KIBS equipped

models). For other than KIBS equipped models, the

signal is sent directly to the ECU.

The ECU uses the wheel rotation sensor signal for KTRC

...