NOTE

Mark and record the locations of the valve lifters and shims so that they can be reinstalled in their original positions.

a + b – c = d

[a] Present Shim Thickness

[b] Measured Valve Clearance

[c] Specified Valve Clearance (Mean Value = 0.195 mm (Exhaust), 0.185 mm (Intake))

[d] Replace Shim Thickness

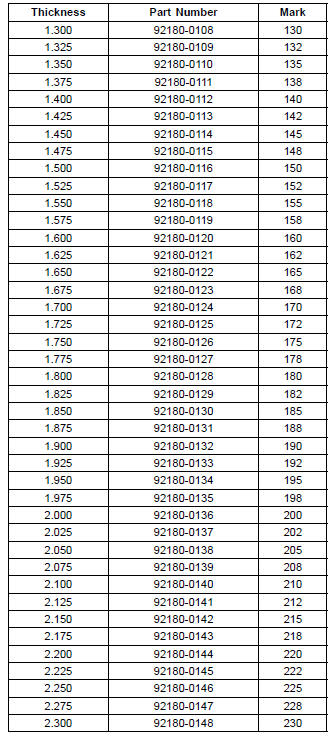

Example (Exhaust): 1.600 + 0.28 – 0.195 = 1.685 mm

Exchange the shim for the 1.675 size shim.

Adjustment Shims

NOTICE

Be sure to remeasure the clearance after selecting a shim. The clearance can be out of the specified range because of the shim tolerance.

If there is no valve clearance, use a shim that is a few sizes smaller, and remeasure the valve clearance.

NOTICE

Do not put shim stock under the shim. This may cause the shim to pop out at high rpm, causing extensive engine damage.

Do not grind the shim. Thismay cause it to fracture, causing extensive engine damage.

Valve Clearance Inspection

Valve Clearance Inspection Air Suction System Damage Inspection

Air Suction System Damage InspectionStarting the Engine

Check that the engine stop switch is

in the

position.

A. Engine Stop Switch

B. Starter Button

Turn the ignition key to “ON”.

Make sure the transmission is in neutral.

A. Neutral Indicator Light

B. Ignition Switch

C. “ON” position

NOTE

The motorcycle is equipped w ...

Drive Chain Slack Inspection

NOTE

Check the slack with the motorcycle setting on its sidestand.

Clean the chain if it is dirty, and lubricate it if it appears

dry.

Check the wheel alignment (see Wheel Alignment Inspection).

Rotate the rear wheel to find the position where the chain

is tightest.

Measure the ver ...

General Information

All rights reserved. No parts of this publication may be reproduced, stored

in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying,

recording or otherwise,

without the prior written permission of Quality Assurance Division/Motorcycle &

Engin ...