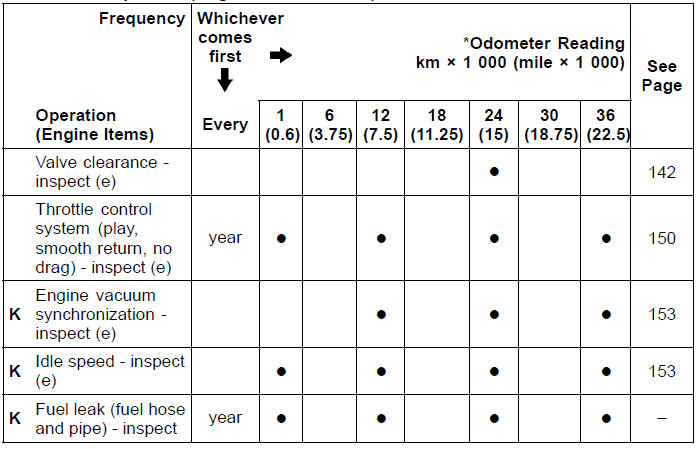

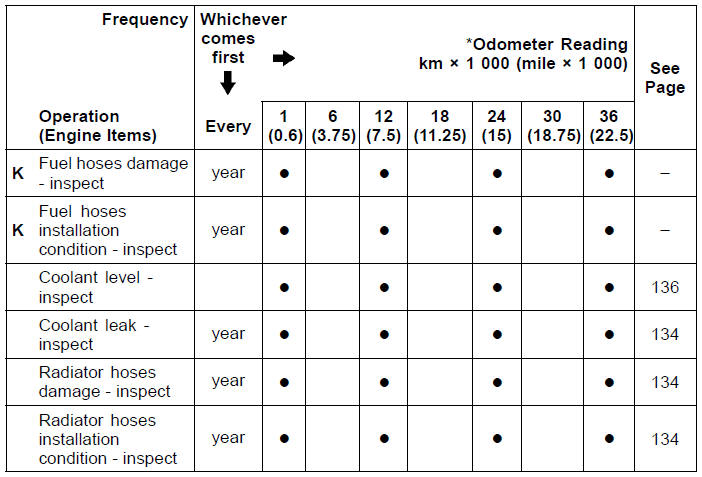

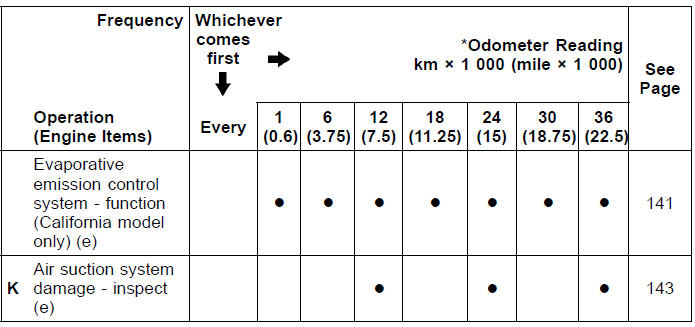

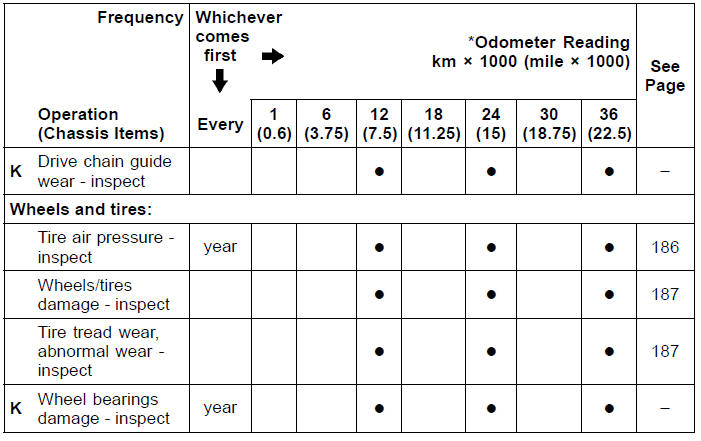

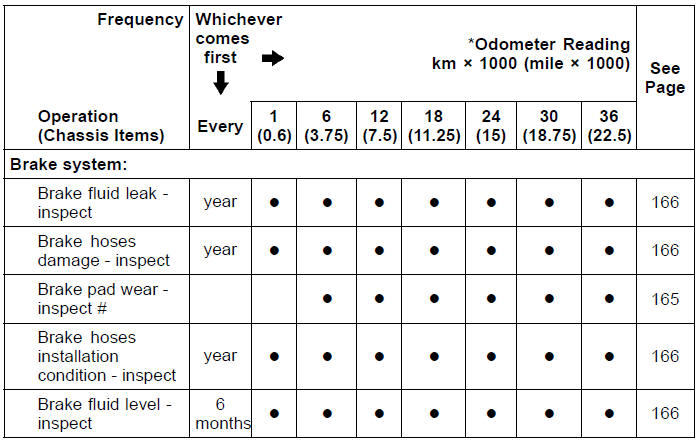

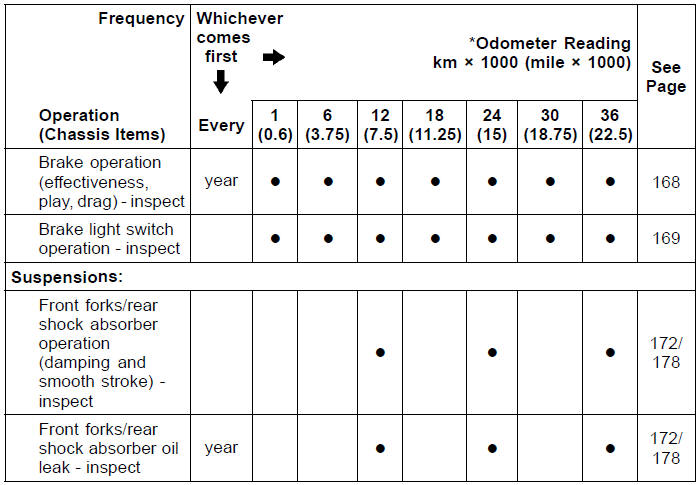

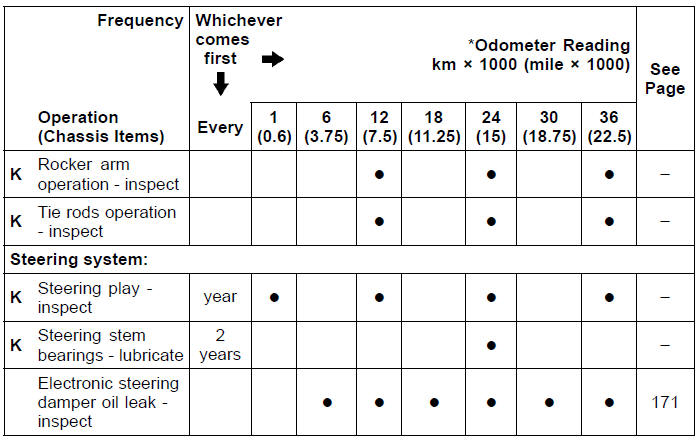

K : Should be serviced by an authorized Kawasaki dealer.

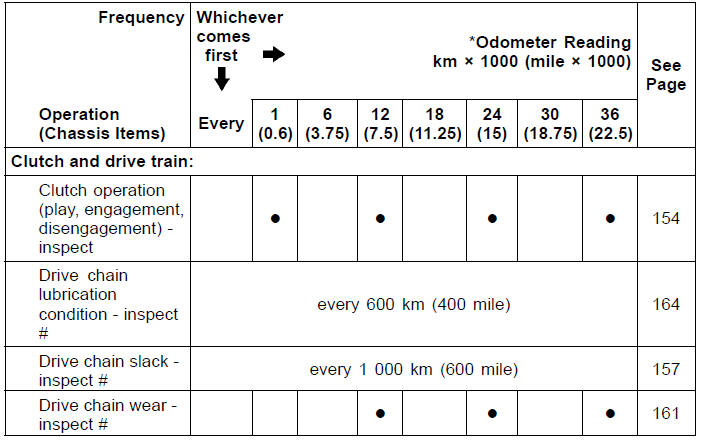

* : For higher odometer readings, repeat at the frequency interval established here.

# : Service more frequently when operating in severe conditions: dusty, wet, muddy, high speed, or frequent starting/stopping.

(e): Emission Related Item

1. Periodic Inspection (Engine Related Items)

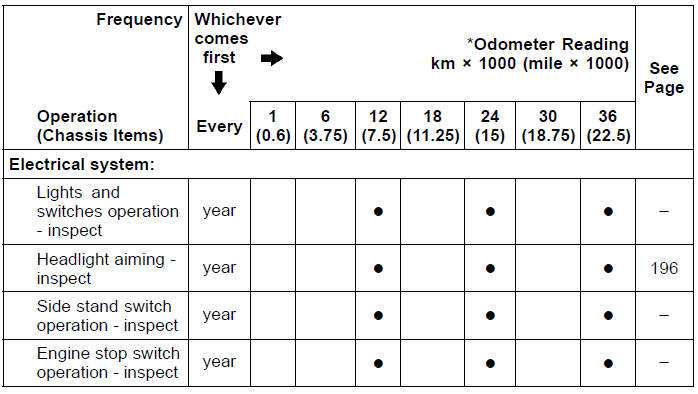

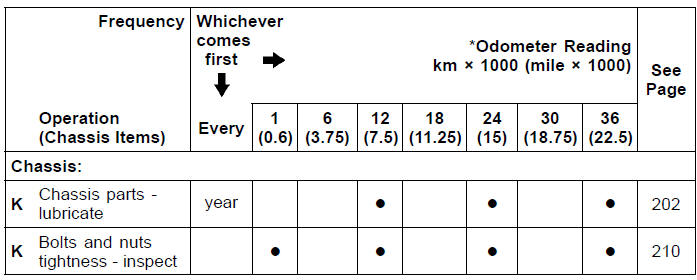

2. Periodic Inspection (Chassis Related Items)

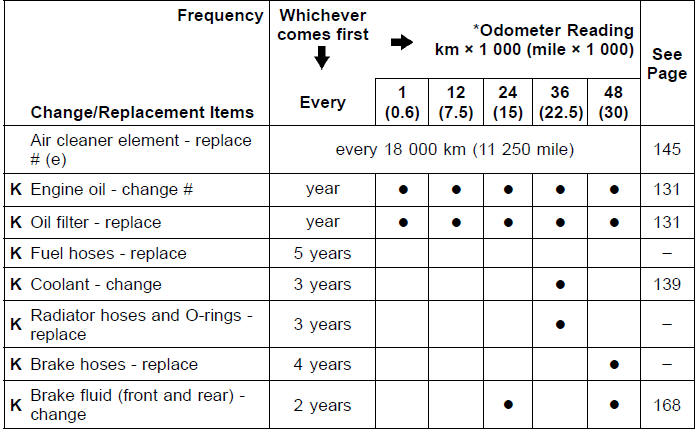

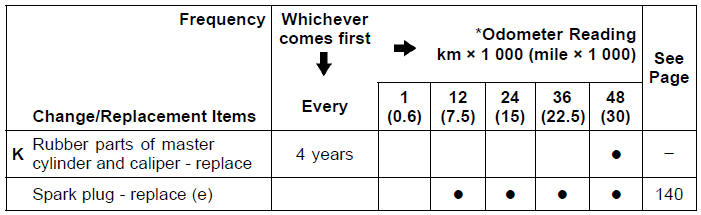

3. Periodic Replacement

Maintenance and adjustment

Maintenance and adjustment Engine Oil

Engine OilSelf-Diagnosis Procedures

NOTE

Use a fully charged battery when conducting

self-diagnosis. Otherwise, the light (LED) and symbol

do not light or blink.

Turn the ignition switch to ON.

When a problem occurs with DFI system and ignition system,

the warning indicator light (LED) [A] goes on and

FI warning symbol ...

Operating Procedures

Clean the seat area carefully.

Coat the seat with machinist’s dye.

Fit a 45° cutter into the holder and slide it into the valve

guide.

Press down lightly on the handle and turn it right or left.

Grind the seating surface only until it is smooth.

NOTICE

Do not grind the seat too ...

Solenoid Valve Inspection (Service Code b 13, b 14, b 17, b 18)

The solenoid valve is built in the KIBS Hydraulic Unit [A].

Therefore the solenoid valve cannot be checked directly.

Perform the Pre-Diagnosis Inspection 1 and 2 (see Inquiries

to Rider in the Brakes chapter).

If any of these service codes appears even if all checks

are ended, replace t ...