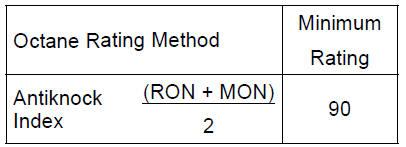

Use clean, fresh unleaded gasoline with a minimum Antiknock Index of 90.

The Antiknock Index is posted on service

station pumps. The octane rating

of a gasoline is a measure of its resistance

to detonation or “knocking.” The

Antiknock Index is an average of the

Research Octane Number (RON) and

the Motor Octane Number (MON) as

shown in the table.

NOTICE

Use minimum of 90 octane gasoline only to prevent severe engine damage.

NOTICE

If engine “knocking” or “pinging” occurs, use a different brand of gasoline of a higher octane rating. If this condition is allowed to continue it can lead to severe engine damage.

Gasoline quality is important.

Fuels of low quality or not meeting standard industry specifications may result in unsatisfactory performance. Operating problems that result from the use of poor quality or nonrecommended fuel may not be covered under your warranty.

Fuel Tank

Fuel Tank Fuels Containing Oxygenates

Fuels Containing OxygenatesIdle Speed Control Valve Actuator Resistance Inspection

Turn the ignition switch to OFF.

Remove the air cleaner housing (see Air Cleaner Housing

Removal in the Fuel System (DFI) chapter).

Disconnect the idle speed control valve actuator connector

[A].

Connect a digital meter to the idle speed control valve

actuator connector [A]

...

Passenger’s Seat Installation

Insert the tab on the rear of the passenger’s

seat into the slot in the

frame.

Insert the projections at the front of

the passenger’s seat into the holes

on the frame.

Push down the front part of the passenger’s

seat until the lock clicks.

A. Passenger’s Seat

B. Proj ...

Technical Information-Power Mode

The rider can choose from three engine power modes to suit their preferences

and road conditions.

The FI ECU controls the engine power by adjusting fuel injection, air intake,

and ignition timing. It

enables three-mode selection: Full Power (Mode F), Middle Power (Mode M), and

Low Power (M ...