Special Tool - Hand Tester: 57001-1394

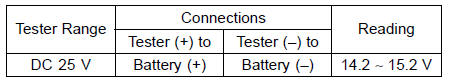

Charging Voltage

If the charging voltage is kept between the values given in the table, the charging system is considered to be working normally.

If the charging voltage is much higher than the values specified in the table, the regulator/rectifier is defective or the regulator/rectifier leads are loose or open.

If the charging voltage does not rise as the engine speed increases, then the regulator/rectifier is defective or the alternator output is insufficient for the loads. Check the alternator and regulator/rectifier to determine which part is defective.

Alternator Rotor Installation

Alternator Rotor Installation Alternator Inspection

Alternator InspectionElectronic Steering Damper Warning Indicator Light

The yellow light functions as the

electronic steering damper warning indicator.

The light and warning symbol

"ESD" go on if there is a malfunction in

the electronic steering damper system.

However, this could also be caused by

trouble with the charging system (e.g.

battery). I ...

Loading and accessories information

WARNINGIncorrect loading, improper installation

or use of accessories,

or modification of your motorcyclemay

result in an unsafe riding

condition. Before you ride the

motorcycle, make sure it is not

overloaded and that you have

followed these instructions.

With the ...

Rear Wheel Removal

Raise the rear wheel off the ground with the stand [A].

Remove:

Cotter Pin [A]

Rear Axle Nut [B]

Washer [C]

Rear Axle [D] (from Right Side)

Remove the rear wheel rotation sensor from the caliper

bracket (see Rear Wheel Rotation Sensor Removal in the

Brakes chapter).

...