Main Throttle Sensor [A] Subthrottle Sensor [B] Idle Speed Control Valve Actuator [C] Subthrottle Valve Actuator [D] Intake Air Pressure Sensor #2 [E] Stick Coils #1, #2, #3, #4 [F] Air Switching Valve [G] Intake Air Pressure Sensor #1 [H]

Water Temperature Sensor [A] Primary Fuel Injectors #1, #2, #3, #4 [B]

Battery [A] Exhaust Butterfly Valve Actuator [B] ECU Fuse 15 A [C] Immobilizer (Equipped Models)/Kawasaki Diagnostic System Connector [D] Vehicle-down Sensor [E]

ECU [A] Relay Box [B] (Fuel Pump Relay, Radiator Fan Relay)

Fuel Pump [A]

Secondary Fuel Injectors #1, #2, #3, #4 [A] Intake Air Temperature Sensor [B]

Crankshaft Sensor [A]

Gear Position Switch [A]

Ignition Key [A] (Transponder, Immobilizer System Equipped Models) Immobilizer Antenna [B] (Equipped Models) Ignition Switch [C] Warning Indicator Light (LED) [D]

Immobilizer Amplifier [A] (Equipped Models) Air Intake Solenoid Valve [B] (Other than US, CA and CAL Models)

Oxygen Sensor [A] (Equipped Models)

Front Wheel Rotation Sensor [A]

Rear Wheel Rotation Sensor [A]

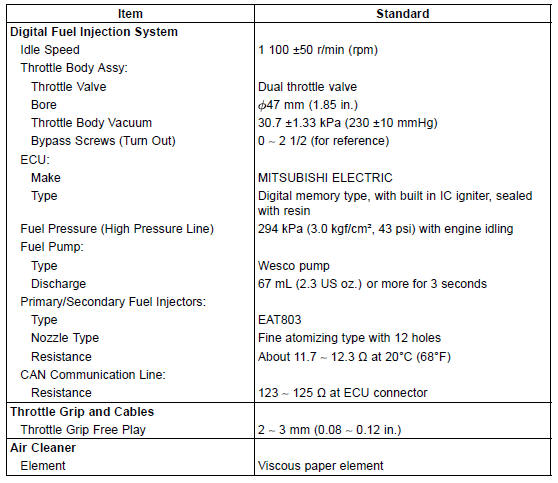

Specifications

Terminal Numbers of ECU Connectors

Terminal Numbers of ECU Connectors Special Tools and Sealant

Special Tools and SealantBolts, Nuts and Fasteners Tightness Inspection

Check the tightness of the bolts and nuts listed here. Also,

check to see that each cotter pin is in place and in good

condition.

NOTE

For the engine fasteners, check the tightness of them

when the engine is cold (at room temperature).

If there are loose fasteners, retighten them to ...

Sport-kawasaki traction control (s-ktrc)

S-KTRC is an intelligent system that

calculates the slip level of the rear

wheel (wheelspin) and is suitable for

sports riding conditions. S-KTRC is

designed to function on public roads.

Acceleration may be delayed under

certain circumstances depending on

road conditions. S-KTRC cannot resp ...

Lubrication

Lubrication is necessary after riding

through rain or on wet roads, or any

time that the chain appears dry.

Use a lubricant for sealed chains to

prevent deterioration of chain seals. If

the chain is especially dirty, clean it

using a cleaner for sealed chains following

the instructions suppli ...