CL: Apply cable lubricant.

EO: Apply engine oil.

G: Apply grease.

HG: Apply high-temperature grease.

L: Apply a non-permanent locking agent.

M: Apply molybdenum disulfide grease.

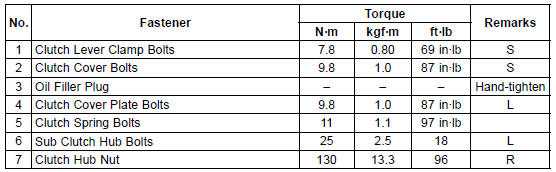

R: Replacement Parts S: Follow the specified tightening sequence.

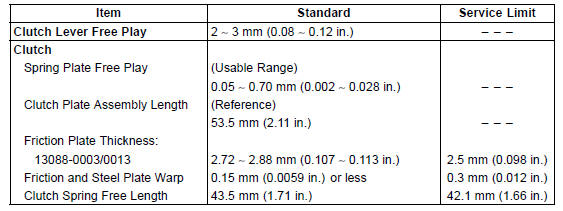

Specifications

Special Tool and Sealant

Clutch Holder:

57001-1243

Liquid Gasket, TB1211F:

92104-0004

Clutch

Clutch Clutch Lever and Cable

Clutch Lever and CableFor Secondary Fuel Injectors

Remove the fuel tank (see Fuel Tank Removal).

Disconnect the secondary fuel injector connector [A].

Connect a digitalmeter to the terminals in each secondary

fuel injector [A].

Measure the secondary fuel injector resistance.

Secondary Fuel Injector Resistance

Standard: Abo ...

Camshaft Chain Tensioner Removal

NOTICE

This is a non-return type camshaft chain tensioner.

The push rod does not return to its original position

once it moves out to take up camshaft chain slack.

Observe all the rules listed below.

When removing the tensioner, do not take out the

mounting bolts only halfway. Retighteni ...

Starter Clutch Inspection

Remove:

Torque Limiter Cover (see Torque limiter Removal)

Turn the torque limiter [A] by hand. The torque limiter

should turn forward freely [B], but should not turn backward.

If the starter clutch does not operate as it should or if it

makes noise, go to the next step.

Disassem ...