The self-diagnosis system is monitoring the following mechanisms.

DFI System and Ignition System

S-KTRC System

Immobilizer System (Equipped Models)

KIBS and ABS (Equipped Models)

ESD (Electronic Steering Damper) System

(ZX1000JD/KD)

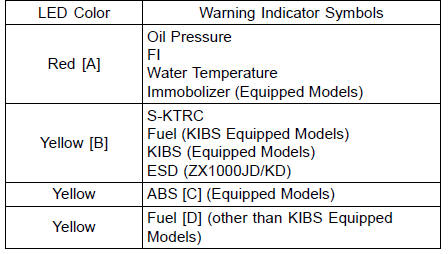

The following warning indicator lights (LED) are used for

symbols of below table.

The self-diagnosis system has two modes and can be switched to another mode by operating the meter unit.

User Mode

The ECU notifies the rider of troubles in DFI system, ignition system, S-KTRC system and immobilizer system (equipped models) by lighting or blinking the warning indicator light (LED) [A], FI warning symbol [B] and immobilizer warning symbol [C] when DFI, ignition, S-KTRC and immobilizer system parts are faulty, and initiates fail-safe function. In case of serious troubles, ECU stops the injection and ignition operations.

For KIBS and ABS system (equipped models), the KIBS hydraulic unit notifies the rider of troubles in KIBS and ABS system by lighting or blinking the red warning indicator light (LED) [A], KIBS warning symbol [B] and ABS indicator light (LED) [C] when KIBS and ABS parts are faulty, and initiates fail-safe function.

For ESD system (ZX1000JD/KD), the ESD ECU notifies the rider of troubles in ESD system by lighting the yellow warning indicator light (LED) and ESD warning symbol [D] when ESD parts are faulty, and initiates fail-safe function.

Dealer Mode

The LCD (Liquid Crystal Display) displays the service code(s) [A] to show the problem(s) which the above system has at the moment of diagnosis.

Self-Diagnosis

Self-Diagnosis Self-Diagnosis Procedures

Self-Diagnosis ProceduresClutch

Due to friction plate wear and clutch

cable stretch over a long period of use,

the clutch operation should be checked

each day before riding the motorcycle,

and must be adjusted in accordance

with the Periodic Maintenance Chart.

Inspection

Check that the clutch lever operates

properly an ...

Wheel Bearing Damage Inspection

Raise the front wheel off the ground with the jack (see

Front Wheel Removal in the Wheels/Tires chapter).

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

Turn the handlebar all the way to the right or left.

Inspect the roughness of the front wheel bearing by moving

[A] ...

Special Tools and Sealant

Oil Pressure Gauge, 5 kgf/cm²:

57001-125

Hand Tester:

57001-1394

Needle Adapter Set:

57001-1457

Extension Tube:

57001-1578

Fuel Pressure Gauge Adapter:

57001-1593

Fuel Hose:

57001-1607

Measuring Adapter:

57001-1700

Liquid Gasket, TB1211:

56019-120

...