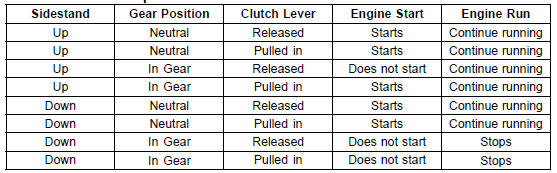

Sidestand Switch Operation

If the sidestand switch operation does not work, inspect or replace the following parts.

Battery (see Charging Condition Inspection in the Electrical System chapter)

Main Fuse 30 A (see Fuse Inspection in the Electrical System chapter) Ignition Fuse 15 A (see Fuse Inspection in the Electrical System chapter) Ignition Switch (see Switch Inspection in the Electrical System chapter) Sidestand Switch (see Switch Inspection in the Electrical System chapter) Engine Stop Switch (see Switch Inspection in the Electrical System chapter) Starter Button (see Switch Inspection in the Electrical System chapter) Gear Position Switch (see Gear Position Switch Inspection in the Electrical System chapter) Starter Lockout Switch (see Switch Inspection in the Electrical System chapter) Starter Relay (see Starter Relay Inspection in the Electrical System chapter) Relay Box (see Relay Circuit Inspection in the Electrical System chapter) Starter Circuit Relay (see Relay Circuit Inspection in the Electrical System chapter) Harness (see Wiring Inspection in the Electrical System chapter)

If the all parts are good condition, replace the ECU (see ECU Removal/Installation in the Fuel System (DFI) chapter).

Headlight Aiming Adjustment

Headlight Aiming Adjustment Engine Stop Switch Operation Inspection

Engine Stop Switch Operation InspectionDrive Chain Slack Inspection

Refer to the Drive Chain Slack Inspection in the Periodic

Maintenance chapter.

Drive Chain Slack Adjustment

Refer to the Drive Chain Slack Adjustment in the Periodic

Maintenance chapter.

Wheel Alignment Inspection/Adjustment

Refer to the Wheel Alignment Inspection in the Periodic

Maintenance ...

Rear Brake Pad Installation

Check that the pad spring is in place on the caliper.

Push the caliper piston in as far as it will go.

Install the piston side pad [A] first, and then another pad.

Fit the brake pad end into the recess [B] of the caliper

holder.

Install the pad pin and the plug.

Tighten:

Torque - ...

Engine Oil

In order for the engine, transmission,

and clutch to function properly, maintain

the engine oil at the proper level,

and change the oil and replace the oil

filter in accordance with the Periodic

Maintenance Chart. Not only do dirt

and metal particles collect in the oil, but

the oil itself los ...