Main Throttle Sensor [A] Subthrottle Sensor [B] Idle Speed Control Valve Actuator [C] Subthrottle Valve Actuator [D] Intake Air Pressure Sensor #2 [E] Stick Coils #1, #2, #3, #4 [F] Air Switching Valve [G] Intake Air Pressure Sensor #1 [H]

Water Temperature Sensor [A] Primary Fuel Injectors #1, #2, #3, #4 [B]

Battery [A] Exhaust Butterfly Valve Actuator [B] ECU Fuse 15 A [C] Immobilizer (Equipped Models)/Kawasaki Diagnostic System Connector [D] Vehicle-down Sensor [E]

ECU [A] Relay Box [B] (Fuel Pump Relay, Radiator Fan Relay)

Fuel Pump [A]

Secondary Fuel Injectors #1, #2, #3, #4 [A] Intake Air Temperature Sensor [B]

Crankshaft Sensor [A]

Gear Position Switch [A]

Ignition Key [A] (Transponder, Immobilizer System Equipped Models) Immobilizer Antenna [B] (Equipped Models) Ignition Switch [C] Warning Indicator Light (LED) [D]

Immobilizer Amplifier [A] (Equipped Models) Air Intake Solenoid Valve [B] (Other than US, CA and CAL Models)

Oxygen Sensor [A] (Equipped Models)

Front Wheel Rotation Sensor [A]

Rear Wheel Rotation Sensor [A]

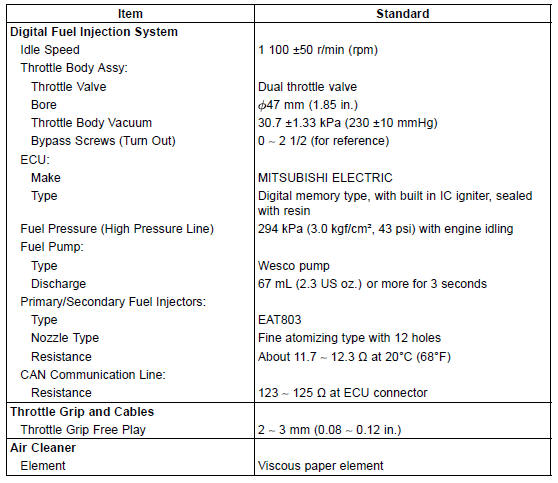

Specifications

Terminal Numbers of ECU Connectors

Terminal Numbers of ECU Connectors Special Tools and Sealant

Special Tools and SealantWater Pump Housing Disassembly

NOTICE

Do not damage the hole wall of the water pump

housing.

Insert a bar [A] into the pump housing [B], and hammer

evenly around the circumference of the mechanical seal

bottom [C].

Take the oil seal [A] out of the housing [B] with a hook [C].

...

Passenger’s Seat Installation

Insert the tab on the rear of the passenger’s

seat into the slot in the

frame.

Insert the projections at the front of

the passenger’s seat into the holes

on the frame.

Push down the front part of the passenger’s

seat until the lock clicks.

A. Passenger’s Seat

B. Proj ...

Exploded View

25. “1T” marked side faces up.

26. “T2” marked side faces up.

27. Hollow mark faces exhaust side.

G: Apply grease.

L: Apply a non-permanent locking agent.

LG: Apply liquid gasket.

M: Apply molybdenum disulfide grease.

MO: Apply molybdenum disulfide oil solution.

...