NOTE

Do not turn the bolts [A] because the reflector in the headlight comes off.

(In the photo, the headlight unit has been removed for clarity.)

NOTE

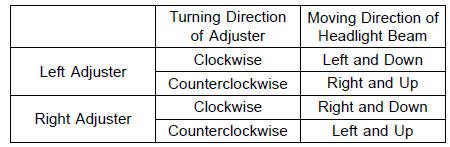

The left adjuster [A] and right adjuster [B] can move the

direction of the headlight beam to up, down, left and

right by turning each adjuster itself as the below table.

NOTE

On high beam, the brightest points should be slightly below horizontal with the motorcycle on its wheels and the rider seated. Adjust the headlight to the proper angle according to local regulations.

NOTE

For US model, the proper angle is 0.4В° below horizontal.

This is 50 mm (2 in.) drop at 7.6 m (25 ft) measured from the center of the headlight with the motorcycle on its wheels and the rider seated.

50 mm (2 in.) [A] Center of Brightest Spot [B] 7.6 m (25 ft) [C] Height of Headlight Center [D]

Lights and Switches Operation Inspection

Lights and Switches Operation Inspection Sidestand Switch Operation Inspection

Sidestand Switch Operation InspectionFront Footpeg Position

The right and left front footpegs can

be selected to one of two positions to

suit the front preferences. Have the

front footpeg positions changed by an

authorized Kawasaki dealer.

A. Bolts

B. Upper Position (Standard)

C. Lower Position

NOTE

Install the front footpegs with same

heig ...

Steering Play Inspection

Remove the lower fairings (see Lower Fairing Removal in

the Frame chapter).

Raise the front wheel off the ground with the jack.

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

With the front wheel pointing straight ahead, alternately

tap each end of the handlebar. The f ...

Camshaft Runout Inspection

Remove the camshafts (see Camshaft Removal).

Set the camshaft in a camshaft alignment jig or on V

blocks.

Measure the runout with a dial gauge at the specified

place as shown in the figure.

If the runout exceeds the service limit, replace the

camshaft.

Camshaft Runout

Standard: TIR ...