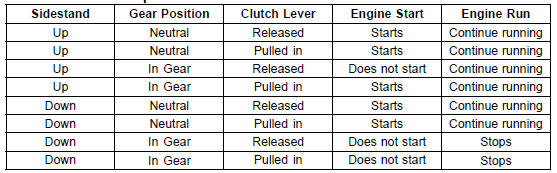

Sidestand Switch Operation

If the sidestand switch operation does not work, inspect or replace the following parts.

Battery (see Charging Condition Inspection in the Electrical System chapter)

Main Fuse 30 A (see Fuse Inspection in the Electrical System chapter) Ignition Fuse 15 A (see Fuse Inspection in the Electrical System chapter) Ignition Switch (see Switch Inspection in the Electrical System chapter) Sidestand Switch (see Switch Inspection in the Electrical System chapter) Engine Stop Switch (see Switch Inspection in the Electrical System chapter) Starter Button (see Switch Inspection in the Electrical System chapter) Gear Position Switch (see Gear Position Switch Inspection in the Electrical System chapter) Starter Lockout Switch (see Switch Inspection in the Electrical System chapter) Starter Relay (see Starter Relay Inspection in the Electrical System chapter) Relay Box (see Relay Circuit Inspection in the Electrical System chapter) Starter Circuit Relay (see Relay Circuit Inspection in the Electrical System chapter) Harness (see Wiring Inspection in the Electrical System chapter)

If the all parts are good condition, replace the ECU (see ECU Removal/Installation in the Fuel System (DFI) chapter).

Headlight Aiming Adjustment

Headlight Aiming Adjustment Engine Stop Switch Operation Inspection

Engine Stop Switch Operation InspectionRear Wheel Installation

Apply high-temperature grease to the grease seal lips.

Fit the collars on the both sides of the hub.

Left Side Collar [A]

Right Side Collar [B] (with Flange)

Engage the drive chain with the rear sprocket.

Install the caliper bracket [A] onto the stopper [B] of the

swingarm.

...

Engine Sprocket Installation

Replace the sprocket washer and axle cotter pin.

Install the engine sprocket onto the output shaft.

Apply molybdenum disulfide oil solution to the threads

and seating surface of the engine sprocket nut.

Tighten:

Torque - Engine Sprocket Nut: 145 N·m (14.8 kgf·m, 107

ft·lb)

NOTE

...

Check 3-1: CAN Communication Line Resistance Inspection

Set the hand tester [A] to the ×1 Ω range and connect it

to the terminal [11] and [12] in the meter unit.

Special Tool - Hand Tester: 57001-1394

CAN Communication Line Resistance (at Meter Unit)

Standard: 122 126 Ω

If the tester reading is not specified, replace the meter ...