Special Tool - Hand Tester: 57001-1394

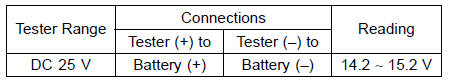

Charging Voltage

If the charging voltage is kept between the values given in the table, the charging system is considered to be working normally.

If the charging voltage is much higher than the values specified in the table, the regulator/rectifier is defective or the regulator/rectifier leads are loose or open.

If the charging voltage does not rise as the engine speed increases, then the regulator/rectifier is defective or the alternator output is insufficient for the loads. Check the alternator and regulator/rectifier to determine which part is defective.

Alternator Rotor Installation

Alternator Rotor Installation Alternator Inspection

Alternator InspectionClutch Installation

Apply engine oil to the needle bearing [A] and the sleeve

[B].

Install:

Needle Bearing

Sleeve

Install the clutch housing [A].

Fit the holes [B] and projections [C].

Engage the clutch housing gear and the crankshaft primary

gear.

Install the spacer [A] and the clutch ...

Turn Signal Switch

When the turn signal switch is

pushed to the left ( ) or right

( ), the corresponding turn signals

blink on and off.

To stop blinking, push the switch in.

Horn Button

When the horn button is pushed, the

horn sounds

LAP/Passing Button

When the LAP/passing button is

pushed, the headlight hi ...

Idle Speed Inspection

Start the engine and warm it up thoroughly.

With the engine idling, turn the handlebar to both sides

[A].

If handlebar movement changes the idle speed, the

throttle cables may be improperly adjusted or incorrectly

routed, or damaged. Be sure to correct any of these

conditions before rid ...