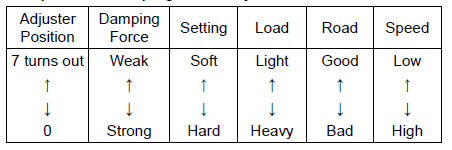

The standard adjuster setting is the 4 1/2 turns out from the fully clockwise position.

| WARNING If both adjusters are not adjusted equally, handling may be impaired and a hazardous condition may result. Be sure the adjusters are set equally. |

Compression Damping Force Adjustment

Rebound Damping Force Adjustment

Rebound Damping Force Adjustment Spring Preload Adjustment

Spring Preload AdjustmentBrake Disc Warp Inspection

Raise the wheel off the ground with the jack.

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

For front disc inspection, turn the handlebar fully to one

side.

Set up a dial gauge against the disc [A] as shown in

the figure and measure disc runout, while turning [B] the

...

Oil and/or Oil Filter Change

To change the engine oil and replace

oil filter, the engine oil drain bolt and

oil filter must be removed. The oil

change and oil filter replacement

should be done by an authorized

Kawasaki dealer.

A. Engine Oil Drain Bolt

A. Oil Filter

WARNINGEngine oil is a toxic s ...

Valve Seat Inspection

Remove the valve (see Valve Removal).

Check the valve seating surface [A] between the valve [B]

and valve seat [C].

Measure the outside diameter [D] of the seating pattern

on the valve seat.

If the outside diameter is too large or too small, repair the

seat (see Valve Seat Repair).

Val ...