Main Throttle Sensor [A] Subthrottle Sensor [B] Idle Speed Control Valve Actuator [C] Subthrottle Valve Actuator [D] Intake Air Pressure Sensor #2 [E] Stick Coils #1, #2, #3, #4 [F] Air Switching Valve [G] Intake Air Pressure Sensor #1 [H]

Water Temperature Sensor [A] Primary Fuel Injectors #1, #2, #3, #4 [B]

Battery [A] Exhaust Butterfly Valve Actuator [B] ECU Fuse 15 A [C] Immobilizer (Equipped Models)/Kawasaki Diagnostic System Connector [D] Vehicle-down Sensor [E]

ECU [A] Relay Box [B] (Fuel Pump Relay, Radiator Fan Relay)

Fuel Pump [A]

Secondary Fuel Injectors #1, #2, #3, #4 [A] Intake Air Temperature Sensor [B]

Crankshaft Sensor [A]

Gear Position Switch [A]

Ignition Key [A] (Transponder, Immobilizer System Equipped Models) Immobilizer Antenna [B] (Equipped Models) Ignition Switch [C] Warning Indicator Light (LED) [D]

Immobilizer Amplifier [A] (Equipped Models) Air Intake Solenoid Valve [B] (Other than US, CA and CAL Models)

Oxygen Sensor [A] (Equipped Models)

Front Wheel Rotation Sensor [A]

Rear Wheel Rotation Sensor [A]

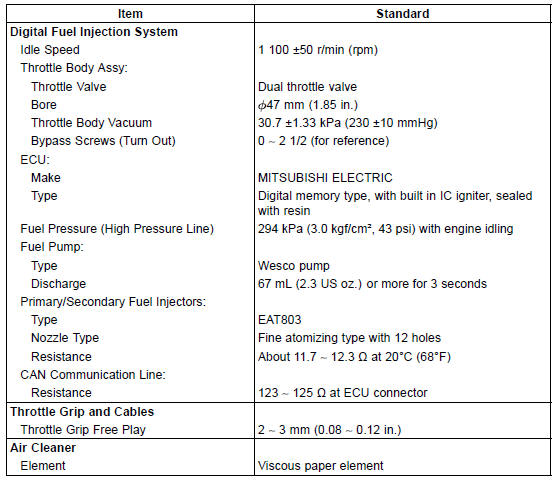

Specifications

Terminal Numbers of ECU Connectors

Terminal Numbers of ECU Connectors Special Tools and Sealant

Special Tools and SealantFor Secondary Fuel Injectors

Remove the fuel tank (see Fuel Tank Removal).

Disconnect the injector connector and connect the harness

adapter [A] between these connectors as shown in

the figure.

Main Harness [B]

Secondary Fuel Injector #1 [C]

Special Tool - Measuring Adapter: 57001-1700

Connect a digital me ...

Multifunction Meter

A. Multifunction Display

Odometer

Trip Meters

Current Mileage

Average Mileage

Fuel consumption

Stop Watch

B. Speedometer

C. Gear Position Indicator

D. Power Mode Indicator

E. S-KTRC Mode Indicator

F. Warning Symbols

G. Lap Counter/Coolant /

Intake Air Temperature

Meter

...

Wear Inspection

Remove the left front footpeg bracket

bolts.

A. Front Footpeg Bracket

B. Bolts

Remove the bolts and chain cover.

A. Bolts

B. Chain Cover

Stretch the chain taut either by using

the chain adjusters, or by hanging a

10 kg (22 lb) weight on the chain.

Measure the lengt ...