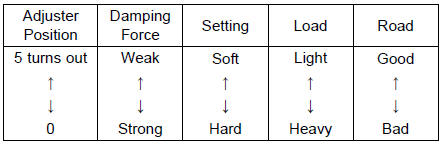

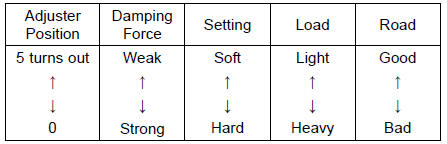

There are two adjustments you can make to the compression damping force.

High Speed Compression Damping Adjuster [A] Low Speed Compression Damping Adjuster [B]

The standard adjuster setting is the 1 3/4 turns out from the fully clockwise position.

High Speed Compression Damping Force Adjustment

NOTE

When turning the high speed compression damping force adjuster (outside), turn the low speed compression damping force adjuster (inside) too. But, the low speed compression damping force (setting position) dose not change.

The standard adjuster setting is the 1 3/4 turns out from the fully clockwise position.

Low Speed Compression Damping Force Adjustment

Rebound Damping Force Adjustment

Rebound Damping Force Adjustment Spring Preload Adjustment

Spring Preload AdjustmentFuel Type

Use clean, fresh unleaded gasoline

with a minimum Antiknock Index of 90.

The Antiknock Index is posted on service

station pumps. The octane rating

of a gasoline is a measure of its resistance

to detonation or “knocking.” The

Antiknock Index is an average of the

Research Octane Number (R ...

Air Cleaner Housing Removal

Remove the fuel tank (see Fuel Tank Removal).

Disconnect the secondary fuel hose [A] from the delivery

pipe of the nozzle assy [B] (see Fuel Hose Replacement

in the Periodic Maintenance chapter).

Disconnect the secondary fuel injector connectors [C].

Free the lead from the grooves [D].

...

Vehicle-down Sensor Output Voltage Inspection

Remove the vehicle-down sensor.

Connect the measuring adapter [A] to the vehicle-down

sensor connectors as shown in the figure.

Special Tool - Measuring Adapter: 57001-1700

Main Harness [B]

Vehicle-down Sensor [C]

Connect a digital meter [D] to the measuring adapter

leads.

V ...