NOTE

Split the crankcase again, measure each clearance between the bearing insert and journal [B] using plastigage (press gauge).

Crankshaft Main Bearing Insert/Journal Clearance

Standard: 0.010  0.034 mm

0.034 mm

(0.0004  0.0013 in.)

0.0013 in.)

Service Limit: 0.06 mm (0.0024 in.)

If the clearance is within the standard, no bearing replacement is required.

If the clearance is between 0.035 mm (0.0014 in.) and the service limit (0.06 mm, 0.0024 in.), replace the bearing inserts [A] with inserts painted blue [B]. Check insert/journal clearance with the plastigage. The clearancemay exceed the standard slightly, but it must not be less than the minimum in order to avoid bearing seizure.

If the clearance exceeds the service limit, measure the diameter of the crankshaft main journal.

Crankshaft Main Journal Diameter

Standard: 34.984 35.000 mm

35.000 mm

(1.3773  1.3780 in.)

1.3780 in.)

Service Limit: 34.96 mm (1.3764 in.)

If any journal has worn past the service limit, replace the crankshaft with a new one.

If themeasured journal diameters [C] are not less than the service limit, but do not coincide with the original diameter markings [D] on the crankshaft, make new marks on it.

Crankshaft Main Journal Diameter Marks

None 34.984  34.992 mm (1.3773

34.992 mm (1.3773

1.3776 in.)

1.3776 in.)

1 34.993  35.000 mm (1.3777

35.000 mm (1.3777

1.3780 in.)

1.3780 in.)

: Crankshaft Main Journal

: Crankshaft Main Journal

Diameter Marks (“1” or No

Mark)

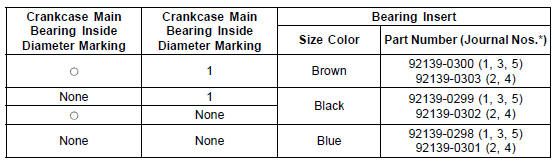

[A]: Crankcase Main Bearing Inside Diameter Marks, “” or no mark.

NOTE

The mark already on the upper crankcase half should almost coincide with the measurement.

Crankcase Main Bearing Inside Diameter Marks

38.000  38.008 mm (1.4961

38.008 mm (1.4961

1.4964 in.)

1.4964 in.)

None 38.009  38.016 mm (1.4964

38.016 mm (1.4964

1.4967 in.)

1.4967 in.)

Size Color [B]

*: The bearing inserts for Nos. 2 and 4 journals have an oil groove, respectively.

Crankshaft Runout Inspection

Crankshaft Runout Inspection Pistons

PistonsHow Do I Get Warranty Service?

If there is a problem with your vehicle within the limited warranty period,

you will

need to schedule a service appointment and provide any maintenance records to

an authorized Kawasaki dealer for inspection and diagnosis. You can go to any

Kawasaki dealer for warranty repairs. Your Kawasaki de ...

Fuel Consumption

This display mode shows the fuel

consumption in Liter or Gallon by numerical

value counted from the start of

measuring to present time.

A. Fuel Consumption

B. “L”

While the fuel consumption is displayed,

push the lower button and

hold it in until the fuel consumption

values re ...

Crankcase Halves Assembly

Install:

Crankshaft (see Crankshaft Installation)

Connecting Rods (see Connecting Rod Installation)

Using a cleaning fluid, clean off any oil or dirt on the mating

surface of the crankcase halves.

Apply liquid gasket to the mating surface of the lower

crankcase half as shown in the fi ...