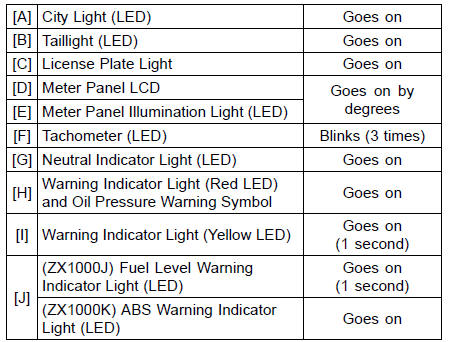

First Step

If the following light does not go on, inspect the meter unit (see Meter Unit Inspection in the Electrical System chapter).

Meter Panel LCD

Meter Panel Illumination Light (LED)

Neutral Indicator Light (LED)

Warning Indicator Light (Red LED)

Warning Indicator Light (Yellow LED)

(ZX1000J) Fuel Level Warning Indicator Light (LED)

(ZX1000K) ABS Warning Indicator Light (LED)

If the light does not go on, inspect or replace the following parts.

Battery (see Charging Condition Inspection in the Electrical System chapter) City Light (see City Light Removal/Installation in the Electrical System chapter) License Plate Light Bulb (see License Plate Light Bulb Replacement in the Electrical System chapter) ECU (see ECU Power Supply Inspection in the Fuel System (DFI) chapter) Main Fuse 30 A, Meter Fuse 10 A and Brake Light/Horn Fuse 10 A (see Fuse Inspection in the Electrical System chapter) Ignition Switch (see Switch Inspection in the Electrical System chapter) Oil Pressure Switch (see Switch Inspection in the Electrical System chapter) Gear Position Switch (see Gear Position Switch Inspection in the Electrical System chapter) Harness (see Wiring Inspection in the Electrical System chapter)

For models equipped with an immobilizer system, warning indicator light (Red LED) will blinks. Refer to the Immobilizer System (Equipped Models) section in the Electrical System chapter.

If the light does not go off, replace the ignition switch.

Second Step (∼ ZX1000JC/KC)

If the light does not go on, inspect or replace the ignition switch (see Switch Inspection in the Electrical System chapter).

Third Step

If the each light does not flash, inspect or replace the following parts.

Front Turn Signal Light (see Upper Fairing Assembly Removal/ Installation in the Frame chapter) Rear Turn Signal Light Bulb (see Rear Turn Signal Light Bulb Replacement in the Electrical System chapter) Turn Signal Indicator Light (LED) (seeMeter Unit Inspection in the Electrical System chapter) Turn Signal Relay Fuse 10 A (see Fuse Inspection in the Electrical System chapter) Turn Signal Switch (see Switch Inspection in the Electrical System chapter) Turn Signal Relay (see Turn Signal Relay Inspection in the Electrical System chapter) Harness (see Wiring Inspection in the Electrical System chapter)

If the light does not go off, inspect or replace the following parts.

Turn Signal Switch (see Switch Inspection in the Electrical System chapter) Turn Signal Relay (see Turn Signal Relay Inspection in the Electrical System chapter)

Fourth Step

If the low beam headlight does not go on, inspect or replace the following parts.

Headlight Low Beam Bulb (see Headlight Bulb Replacement in the Electrical System chapter) Headlight Fuse 15 A (see Fuse Inspection in the Electrical System chapter) Dimmer Switch (see Switch Inspection in the Electrical System chapter) Headlight Relay (see Relay Circuit Inspection in the Electrical System chapter) Harness (see Wiring Inspection in the Electrical System chapter)

If the high beam headlight and/or high beam indicator light (LED) does not go on, inspect or replace the following parts.

Headlight High Beam Bulb (see Headlight Bulb Replacement in the Electrical System chapter) Dimmer Switch (see Switch Inspection in the Electrical System chapter)

If the headlights and high beam indicator light (LED) does go off, inspect or replace the headlight relay (see Relay Circuit Inspection in the Electrical System chapter).

Headlight Aiming Inspection

If the headlight beam points to one side rather than straight ahead, adjust the headlight aiming.

Headlight Aiming Adjustment

Headlight Aiming AdjustmentSport-kawasaki traction control (s-ktrc)

S-KTRC is an intelligent system that

calculates the slip level of the rear

wheel (wheelspin) and is suitable for

sports riding conditions. S-KTRC is

designed to function on public roads.

Acceleration may be delayed under

certain circumstances depending on

road conditions. S-KTRC cannot resp ...

Headlight Bulb Replacement

Turn the cover [A] counterclockwise, and remove it.

Disconnect the headlight connector [A].

Open the clamp [B], and remove the bulb.

NOTICE

When handling the quartz-halogen bulb, never

touch the glass portion with bare hands. Always

use a clean cloth. Oil contamination from hand ...

Parking

WARNINGOperating or parking the vehicle

near flammable materials can

cause a fire, and can result in

property damage or severe personal

injury.

Do not idle or park your vehicle

in an area where tall or dry vegetation,

or other flammable materials

could come into cont ...