NOTE

The free play adjustment is performed by replacing the steel plate(s).

Spring Plate Free Play

Usable Range: 0.05  0.70 mm (0.002

0.70 mm (0.002

0.028 in.)

0.028 in.)

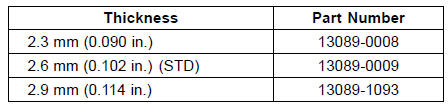

Replace the following steel plate(s).

NOTE

Do not use the steel plate of 2.3 mm (0.090 in.) and 2.9 mm (0.114 in.) thickness at the same time.

Clutch Plate Assembly Length (Reference Information)

Clutch Hub [A] Spring Seat [B] Spring [C] Sub Clutch Hub [D] Sub Clutch Hub Bolts [E] New Friction Plates [F] Steel Plates [G] Spring Plate [H] Clutch Springs [I] Clutch Spring Holders [J] Clutch Spring Bolts [K]

Torque - Clutch Spring Bolts: 11 N·m (1.1 kgf·m, 97 in·lb)

Clutch Plate Assembly Length (Reference) 53.5 mm (2.11 in.)

NOTE

The length of the clutch plate assembly changes by the steel plate thickness.

Spring Plate Free Play Measurement

Spring Plate Free Play Measurement Clutch Plate, Wear, Damage Inspection

Clutch Plate, Wear, Damage InspectionRear Master Cylinder Removal

Unscrew the brake hose banjo bolt [A] and remove the

brake hose (see Brake Hose and Pipe Replacement in

the Periodic Maintenance chapter).

Remove:

Rear Master Cylinder Mounting Bolts [B]

Foot Guard [C]

Screw and Stopper [D]

Bolt [E]

Front Footpeg Bracket Bolts [F]

Cable Guide [G ...

Chassis Parts Lubrication

Before lubricating each part, clean off any rusty spots with

rust remover and wipe off any grease, oil, dirt, or grime.

Lubricate the points listed below with indicated lubricant.

NOTE

Whenever the vehicle has been operated under

wet or rainy conditions, or especially after using a

high ...

Fuel Tank Cap

To open the fuel tank cap, pull up the

key hole cover. Insert the ignition key

into the fuel tank cap and turn the key

to the right.

To close the cap, push it down into

place with the key inserted. The key

can be removed by turning it to the left

to the original position. Close the key

hol ...