NOTE

Split the crankcase again, measure each clearance between the bearing insert and journal [B] using plastigage (press gauge).

Crankshaft Main Bearing Insert/Journal Clearance

Standard: 0.010  0.034 mm

0.034 mm

(0.0004  0.0013 in.)

0.0013 in.)

Service Limit: 0.06 mm (0.0024 in.)

If the clearance is within the standard, no bearing replacement is required.

If the clearance is between 0.035 mm (0.0014 in.) and the service limit (0.06 mm, 0.0024 in.), replace the bearing inserts [A] with inserts painted blue [B]. Check insert/journal clearance with the plastigage. The clearancemay exceed the standard slightly, but it must not be less than the minimum in order to avoid bearing seizure.

If the clearance exceeds the service limit, measure the diameter of the crankshaft main journal.

Crankshaft Main Journal Diameter

Standard: 34.984 35.000 mm

35.000 mm

(1.3773  1.3780 in.)

1.3780 in.)

Service Limit: 34.96 mm (1.3764 in.)

If any journal has worn past the service limit, replace the crankshaft with a new one.

If themeasured journal diameters [C] are not less than the service limit, but do not coincide with the original diameter markings [D] on the crankshaft, make new marks on it.

Crankshaft Main Journal Diameter Marks

None 34.984  34.992 mm (1.3773

34.992 mm (1.3773

1.3776 in.)

1.3776 in.)

1 34.993  35.000 mm (1.3777

35.000 mm (1.3777

1.3780 in.)

1.3780 in.)

: Crankshaft Main Journal

: Crankshaft Main Journal

Diameter Marks (“1” or No

Mark)

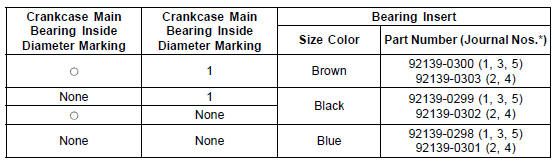

[A]: Crankcase Main Bearing Inside Diameter Marks, “” or no mark.

NOTE

The mark already on the upper crankcase half should almost coincide with the measurement.

Crankcase Main Bearing Inside Diameter Marks

38.000  38.008 mm (1.4961

38.008 mm (1.4961

1.4964 in.)

1.4964 in.)

None 38.009  38.016 mm (1.4964

38.016 mm (1.4964

1.4967 in.)

1.4967 in.)

Size Color [B]

*: The bearing inserts for Nos. 2 and 4 journals have an oil groove, respectively.

Crankshaft Runout Inspection

Crankshaft Runout Inspection Pistons

PistonsTachometer

The tachometer shows the engine

speed in revolutions per minute (r/min,

rpm).

On the right side of the tachometer

face is a portion called the “red zone”.

Engine r/min (rpm) in the red zone is

above maximum recommended engine

speed and is also above the range for

good performance.

...

Coolant Filling

Remove the bolts and quick rivets.

Detach the tabs and remove the right

fairing and cover.

A. Bolts

B. Quick Rivet

C. Large Quick Rivet

D. Tabs

E. Right Fairing and Cover

NOTE

The right fairing and cover uses the

quick rivets and large quick rivet.

The large quick rivet ca ...

Rebound Damping Force Adjustment

To adjust the rebound damping force, turn the rebound

damping adjuster [A] to the desired position.

The standard adjuster setting is the 1 3/4 turns out from

the fully clockwise position.

Rebound Damping Force Adjustment

...