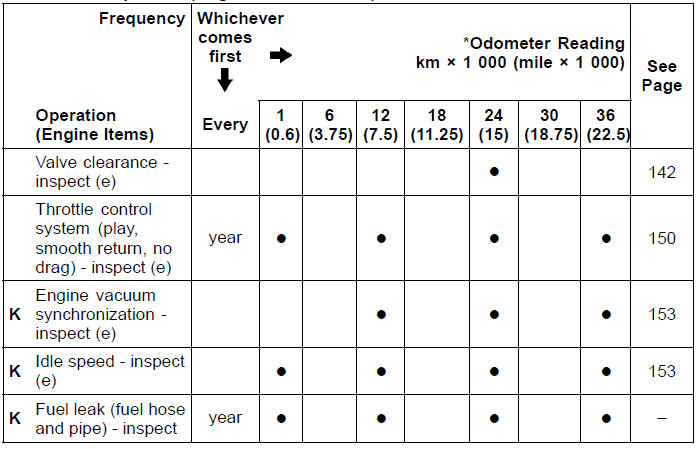

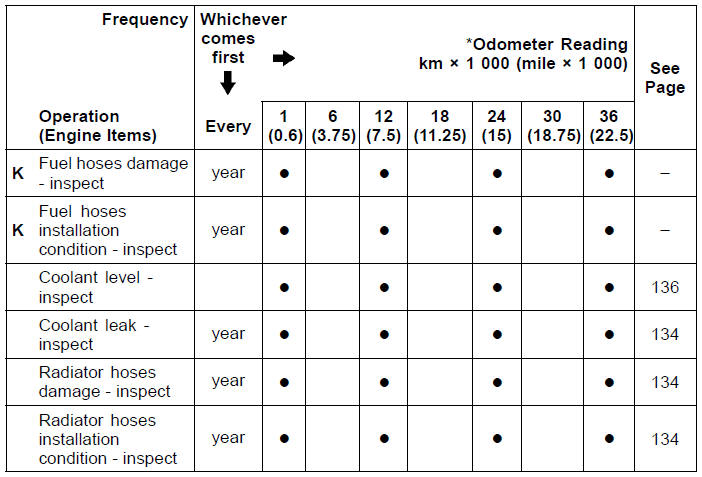

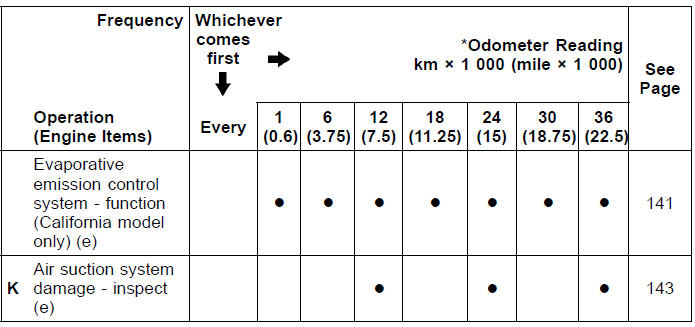

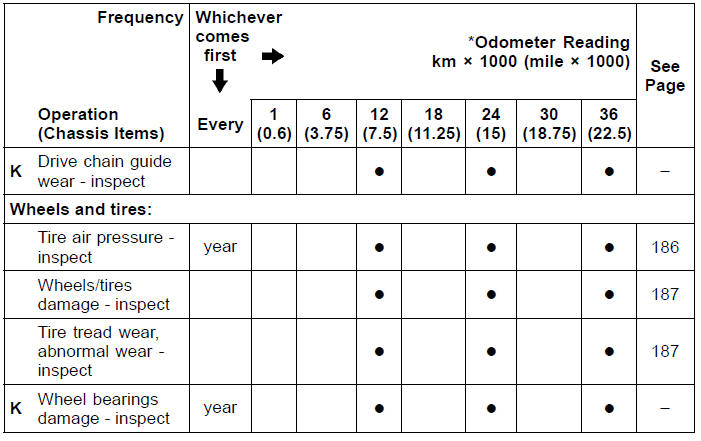

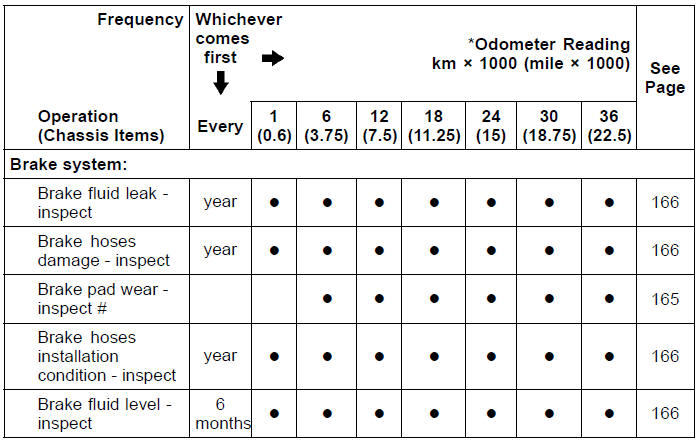

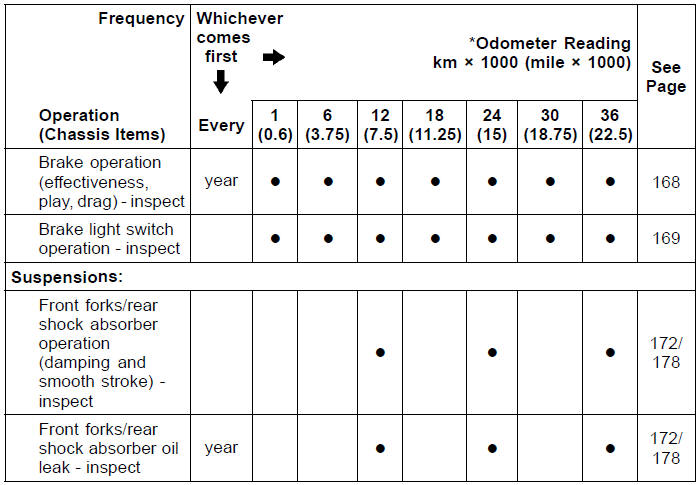

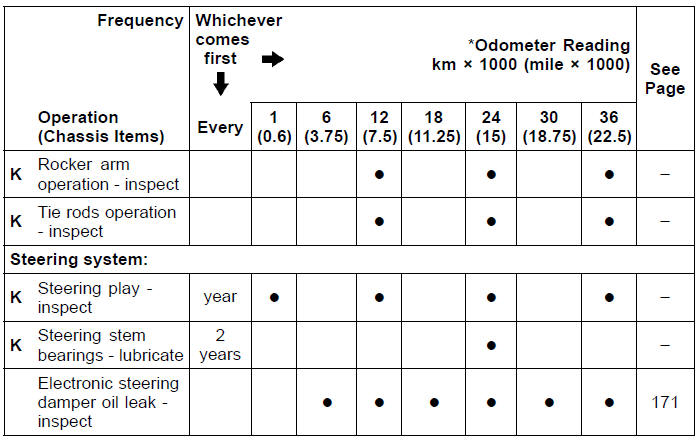

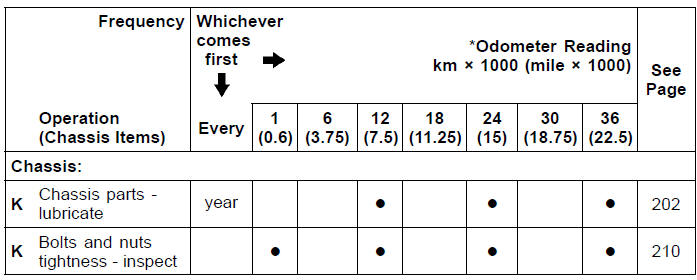

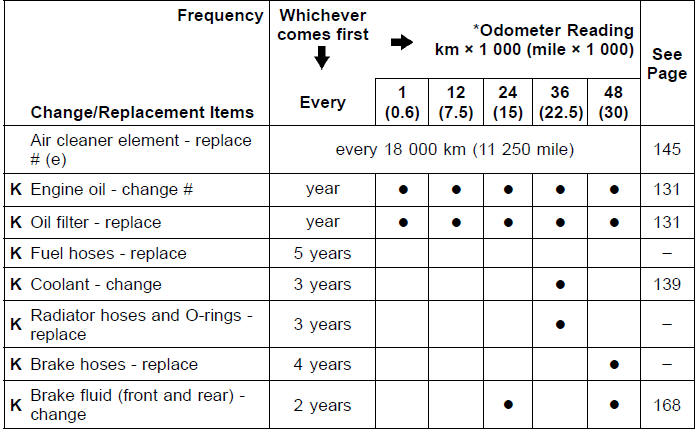

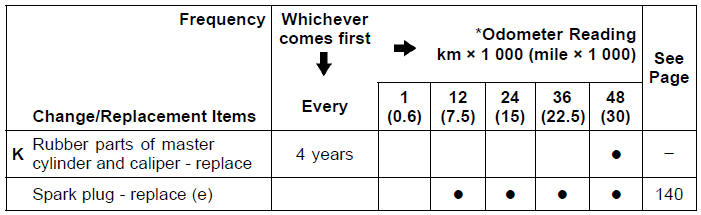

K : Should be serviced by an authorized Kawasaki dealer.

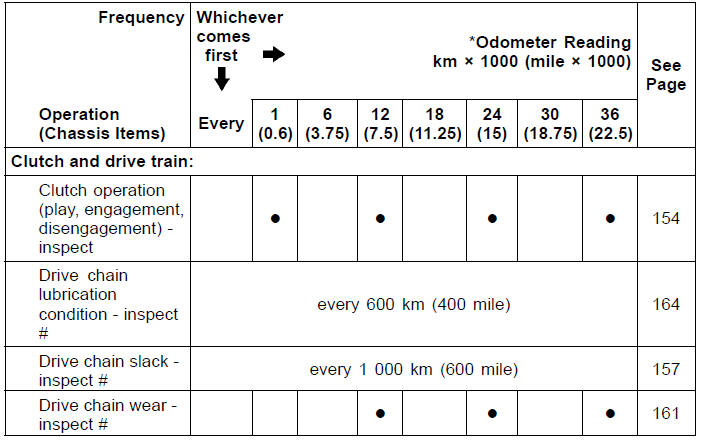

* : For higher odometer readings, repeat at the frequency interval established here.

# : Service more frequently when operating in severe conditions: dusty, wet, muddy, high speed, or frequent starting/stopping.

(e): Emission Related Item

1. Periodic Inspection (Engine Related Items)

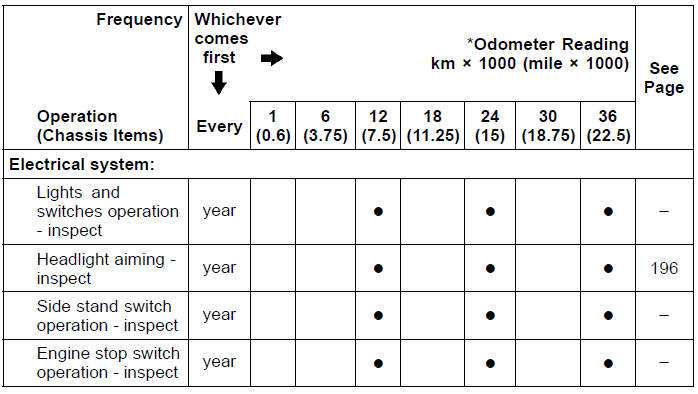

2. Periodic Inspection (Chassis Related Items)

3. Periodic Replacement

Maintenance and adjustment

Maintenance and adjustment Engine Oil

Engine OilECU Communication Error (Service Code 39)

ECU Communication Line Inspection

When the data is not sent from the ECU to the meter unit

for more than about 10 seconds, the service code 39 is

displayed.

The data is sent through the CAN communication line.

The service code 39 is detected with the meter unit.

When the user mode, this commun ...

Swingarm Bearing Installation

Replace the needle bearings, ball bearing, grease seals

and circlip with new ones.

Install the needle bearings, ball bearing, grease seals and

circlip as shown in the figure.

Insert the needle bearing driver [A] into the needle bearing

[B] and press the needle bearing into the housing u ...

RiderŌĆÖs Seat Installation

Insert the tabs on the front of the

riderŌĆÖs seat into the slots in the frame

and secure the seat with mounting

bolts.

Install the seat cover and bolts.

A. RiderŌĆÖs Seat

B. Tabs

C. Slots

D. Stays ...