The self-diagnosis system is monitoring the following mechanisms.

DFI System and Ignition System

S-KTRC System

Immobilizer System (Equipped Models)

KIBS and ABS (Equipped Models)

ESD (Electronic Steering Damper) System

(ZX1000JD/KD)

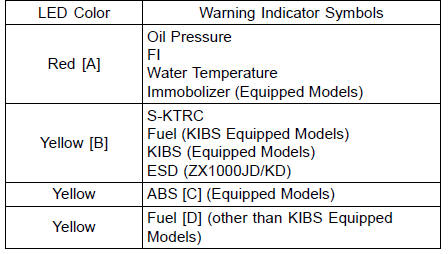

The following warning indicator lights (LED) are used for

symbols of below table.

The self-diagnosis system has two modes and can be switched to another mode by operating the meter unit.

User Mode

The ECU notifies the rider of troubles in DFI system, ignition system, S-KTRC system and immobilizer system (equipped models) by lighting or blinking the warning indicator light (LED) [A], FI warning symbol [B] and immobilizer warning symbol [C] when DFI, ignition, S-KTRC and immobilizer system parts are faulty, and initiates fail-safe function. In case of serious troubles, ECU stops the injection and ignition operations.

For KIBS and ABS system (equipped models), the KIBS hydraulic unit notifies the rider of troubles in KIBS and ABS system by lighting or blinking the red warning indicator light (LED) [A], KIBS warning symbol [B] and ABS indicator light (LED) [C] when KIBS and ABS parts are faulty, and initiates fail-safe function.

For ESD system (ZX1000JD/KD), the ESD ECU notifies the rider of troubles in ESD system by lighting the yellow warning indicator light (LED) and ESD warning symbol [D] when ESD parts are faulty, and initiates fail-safe function.

Dealer Mode

The LCD (Liquid Crystal Display) displays the service code(s) [A] to show the problem(s) which the above system has at the moment of diagnosis.

Self-Diagnosis

Self-Diagnosis Self-Diagnosis Procedures

Self-Diagnosis ProceduresHub Bearing Removal

Remove the wheels (see Front/Rear Wheel Removal),

and take out the following.

Collars

Coupling (Out of rear hub)

Grease Seals

Use the bearing remover to remove the hub bearings [A].

NOTICE

Do not lay the wheel on the ground with the disc

facing down. This can damage or warp the d ...

Lower Crankcase Assembly

Install the ball bearing [A] and the oil level inspection window

[B] until they are bottomed

Apply soap and water solution to the oil level inspection

window before installation.

Install the new circlip [C].

Apply a non-permanent locking agent to the oil passage

plug [D].

Tighten: ...

Release Shaft Installation

Apply grease to the oil seal lips on the upper ridge of the

clutch cover.

Apply engine oil to the needle bearings in the hole of the

clutch cover.

Applymolybdenum disulfide grease to the pusher-holding

portion [A] on the release shaft.

Install the washer [B] and spring [C].

...