The spring preload adjuster is located at the lower end of each front fork leg and can be adjusted.

A. Spring Preload Adjuster

B. Hexagon Wrench

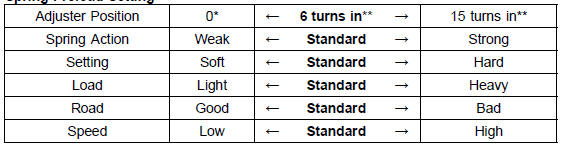

Spring Preload Setting

*: This position is the fully seated position (turned fully counterclockwise).

**: In from the fully seated position (turned fully counterclockwise). This adjustment range may not exactly match the number shown in the table due to small tolerance of production.

Front Fork Inspection

Front Fork Inspection Compression Damping Force Adjuster and Rebound

Damping Force Adjuster Adjustment

Compression Damping Force Adjuster and Rebound

Damping Force Adjuster AdjustmentCamshaft Chain Tensioner Installation

Replace the O-ring [A] with a new one.

Apply grease to the new O-ring.

Release the stopper [B] and push the push rod [C] into the

interior of the tensioner body [D] so that the position of the

push rod is 3 or 4 notches [E] as shown in the figure.

Install the tensioner body so that the ...

CAN Communication (Transmission)/CAN Bus OFF Monitor Inspection (Service Code

b 57) CAN Communication (Reception) Monitor Inspection (Service Code b 58)

Remove:

Seat (see Seat Removal in the Frame chapter)

Immobilizer (Equipped Models)/Kawasaki Diagnostic

System Connector Cap [A]

Measure the CAN communication line resistance.

Immobilizer (Equipped Models)/Kawasaki Diagnostic

System Connector [A]

GY/BL Terminal [B]

LB Ter ...

Gear Position Switch Installation

Securely place the springs [A] and pins [B] into the holes

[C] of the shift drum.

Apply grease to the new O-ring [D].

Install the gear position switch [E].

Apply a non-permanent locking agent to the threads of

the gear position switch screws [F].

Tighten:

Torque - Gear Position Swit ...