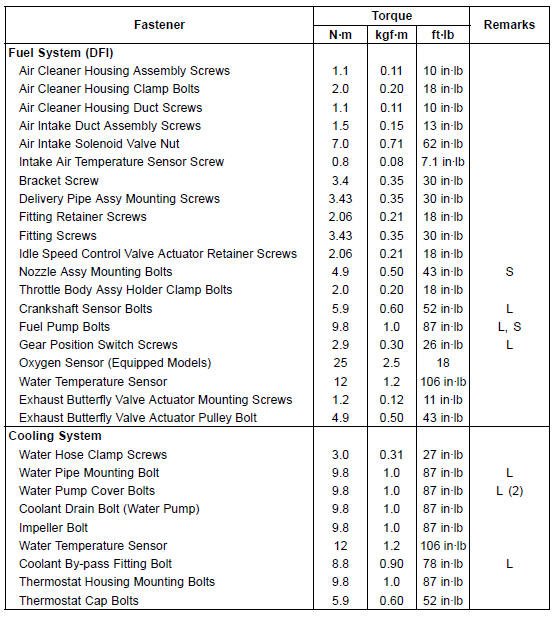

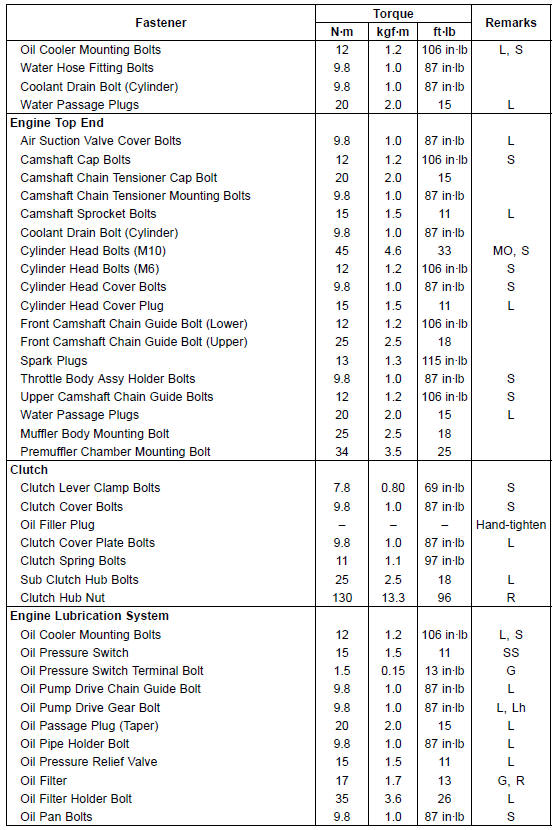

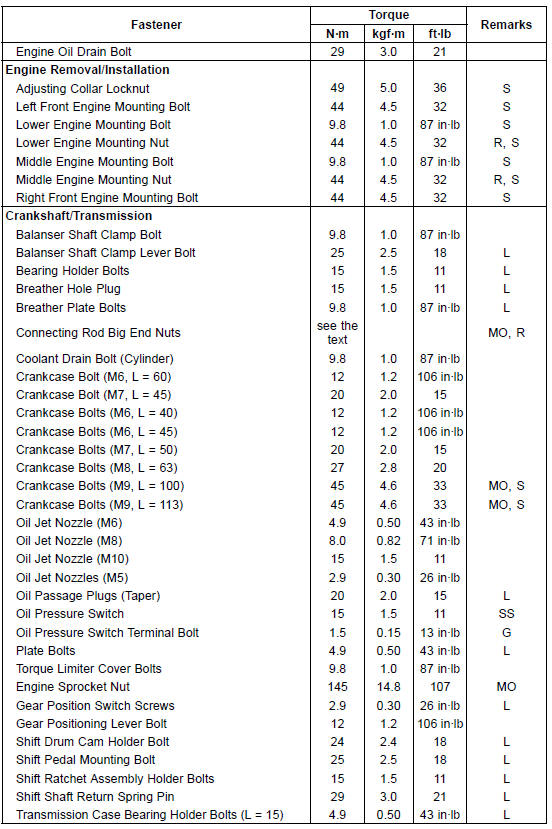

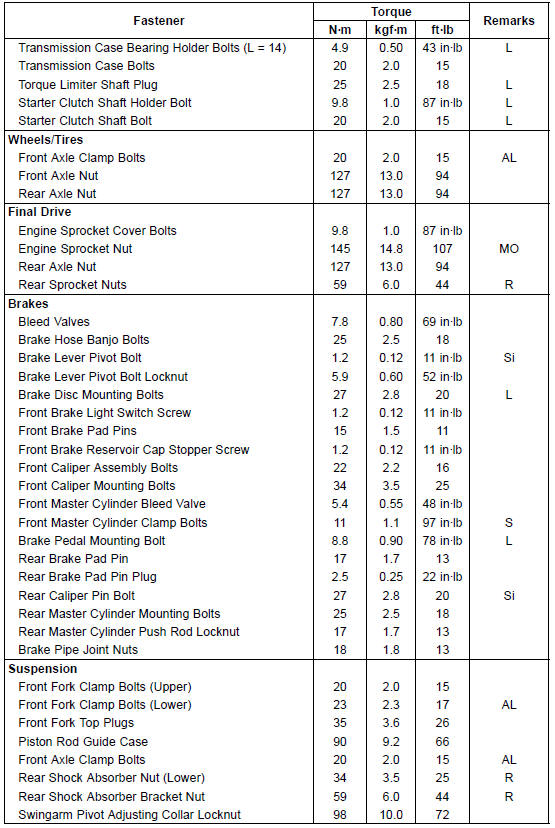

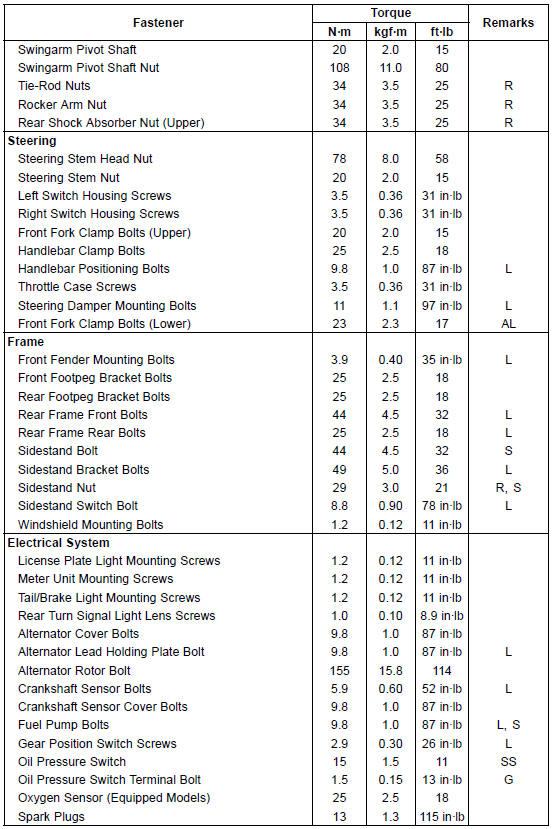

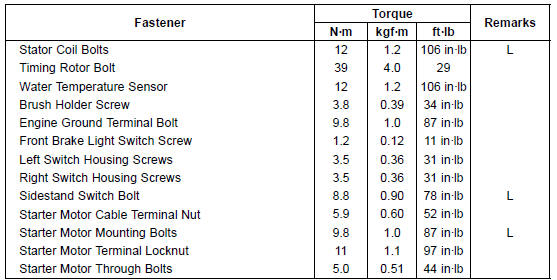

The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean: AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease.

L: Apply a non-permanent locking agent.

Lh: Left-hand Threads

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1)

R: Replacement Parts

S: Follow the specified tightening sequence.

Si: Apply silicone grease (ex. PBC grease).

SS: Apply silicone sealant.

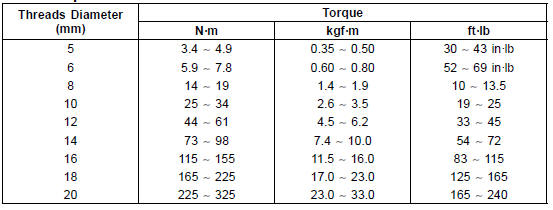

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

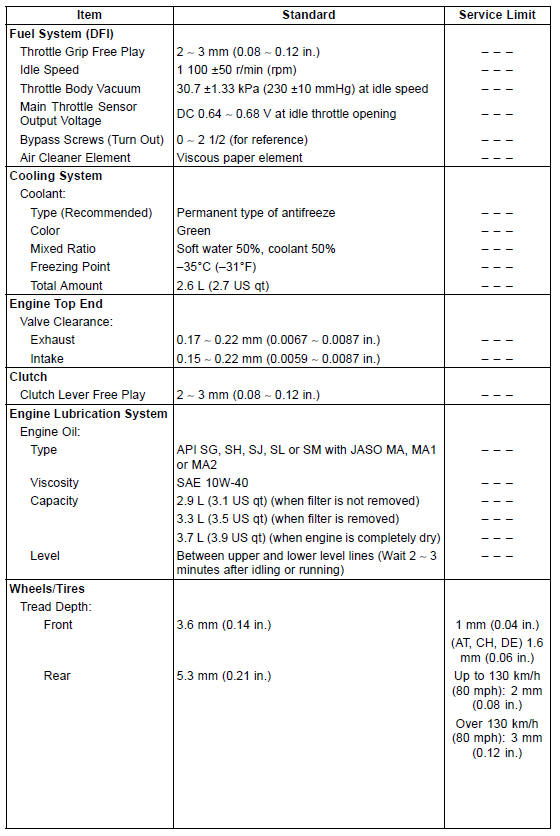

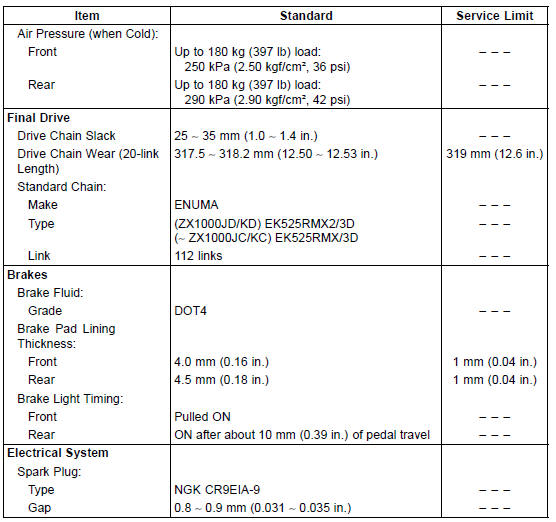

Specifications

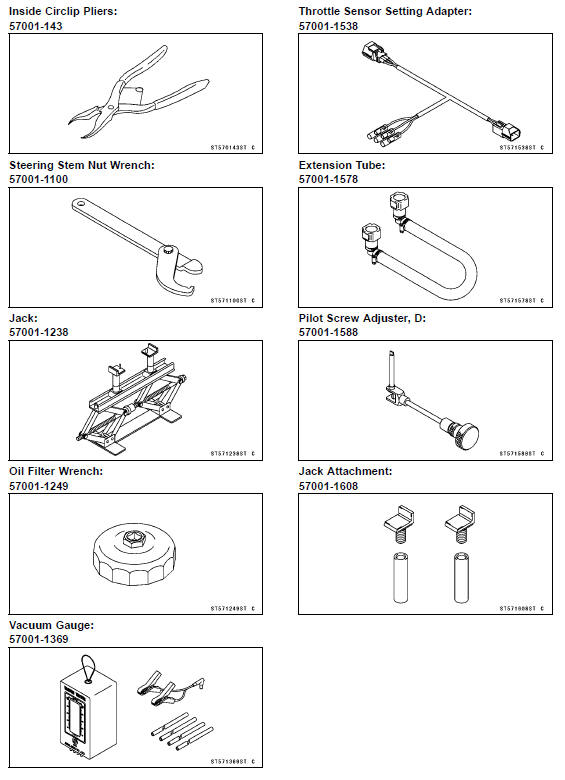

Special Tools

Periodic Maintenance Chart

Periodic Maintenance ChartTransmission Assy Removal

Remove:

Engine Sprocket (see Engine Sprocket Removal in the

Final Drive chapter)

Gear Position Switch (see Gear Position Switch Removal

in the Electrical System chapter)

Collar [A]

O-ring [B]

Remove:

Clutch (see Clutch Removal in the Clutch chapter)

Shift Shaft Assembly ...

Evaporative Emission Control System (California

model only)

This system routes fuel vapors from

the fuel system into the running engine

or stores the vapors in a canister when

the engine is stopped. Although no adjustments

are required, a thorough visual

inspection must be made at the intervals

specified by the Periodic Maintenance

Chart.

Inspection

...

Gear Position Indicator

The gear position indicator shows the

corresponding gear positions where

the transmission is shifted.

For example, when the transmission

is in 6th gear, “6” is displayed.

A. Gear Position Indicator (Normal mode)

NOTE

If the gear position is in the neutral

position, the gear positio ...