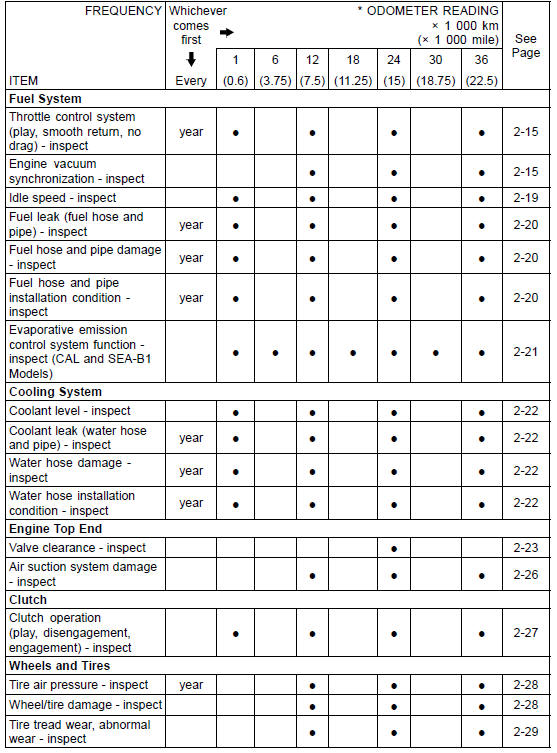

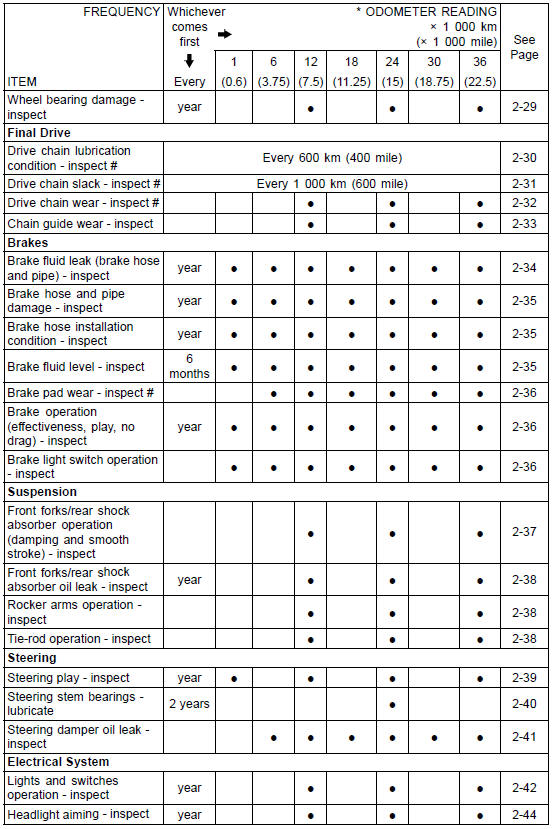

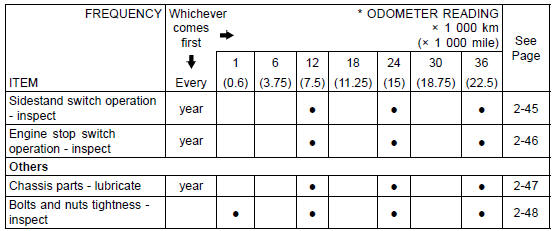

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition. The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

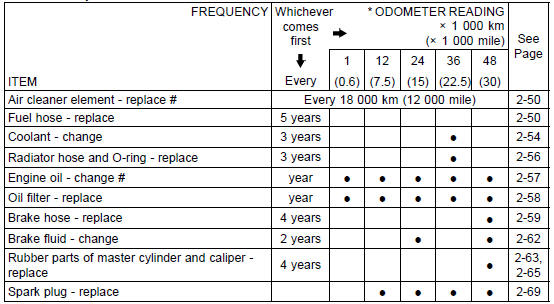

Periodic Replacement Parts

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

Torque and Locking Agent

Torque and Locking AgentSpecial Tools and Sealant

Hand Tester:

57001-1394

Flywheel Puller Assembly, M38 × 1.5/M35 × 1.5:

57001-1405

Peak Voltage Adapter:

57001-1415

Lead Wire - Peak Voltage Adapter:

57001-1449

Key Registration Unit:

57001-1582

Grip:

57001-1591

Flywheel & Pulley Holder:

57001-1605

Rotor Holder:

...

Precautions

1) No need of topping-up

No topping-up is necessary in this battery until it ends its life under

normal use. Forcibly prying

off the seal cap to add water is very dangerous. Never do that.

2) Refreshing charge.

Give refresh charge for 5 to 10 hours with charge current shown in the text

(see ...

Spark Plug Replacement

Remove the stick coils (see Stick Coil Removal in the

Electrical System chapter).

Remove the spark plugs using the 16 mm (0.63 in.) plug

wrench [A] vertically.

Replace the spark plug with new ones.

Standard Spark Plug

Type: NGK CR9EIA-9

Insert the spark plug vertically into the sp ...