Turn Signal Relay [A] Turn Signal Lights [B] 12 V Battery [C]

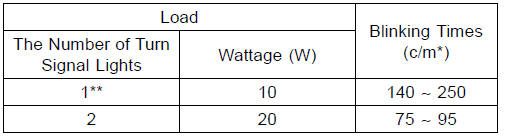

If the lights do not blink as specified, replace the turn signal relay.

Testing Turn Signal Relay

(*): Cycle(s) per minute

(**): Corrected to “one light burned out”.

Turn Signal Light Circuit

1. Ignition Switch

2. Joint Connector A

3. Rear Right Turn Signal Light 12 V 10 W

4. Rear Left Turn Signal Light 12 V 10 W

5. Joint Connector B

6. Battery

7. Main Fuse 30 A

8. Frame Ground

9. Turn Signal Relay

10. Turn Signal Switch

11. Turn Signal Relay Fuse 10 A

12. Fuse Box 1

13. Front Left Turn Signal Light (LED)

14. Front Right Turn Signal Light (LED)

15. Turn Signal Indicator Light (LED)

Rear Turn Signal Light Bulb Replacement

Rear Turn Signal Light Bulb Replacement Air Switching Valve

Air Switching ValveRear Sprocket Removal

Remove the rear wheel (see Rear Wheel Removal in the

Wheels/Tires chapter).

NOTICE

Do not lay the wheel on the ground with the disc

facing down. This can damage or warp the disc.

Place blocks under the wheel so that the disc does

not touch the ground.

Remove:

Rear Sprocket Nu ...

Coolant Change

WARNINGCoolant can be extremely hot and cause

severe

burns, is toxic and very slippery. Do not remove

the radiator cap or attempt to change the coolant

when the engine is hot; allow it cool completely.

Immediately wipe any spilled coolant from tires,

frame, engine or othe ...

Alternator Rotor Installation

Using a cleaning fluid, clean off any oil or dirt on the following

portions and dry them with a clean cloth.

Crankshaft Tapered Portion [A]

Alternator Rotor Tapered Portion [B]

Install the alternator rotor.

Using a cleaning fluid, clean off any oil or dirt on the

washer [A] ...