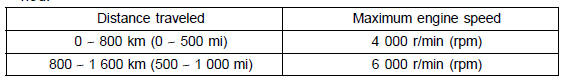

The first 1 600 km (1 000 mi) that the motorcycle is ridden is designated as the break-in period. If the motorcycle is not used carefully during this period, you may very well end up with a “broken down” instead of a “broken in” motorcycle after a few thousand kilometers.

The following rules should be observed during the break-in period.

NOTE

When operating on public roadways, keep maximum speed under traffic low limits.

| WARNING New tires are slippery and may cause loss of control and injury. A break-in period of 160 km (100 miles) is necessary to establish normal tire traction. During break-in, avoid sudden and maximum braking and acceleration, and hard cornering. |

In addition to the above, at 1 000 km (600 mi) it is extremely important that the owner has the initial maintenance service performed by a competent mechanic following the procedures in the Service Manual.

Front Footpeg Position

Front Footpeg PositionPiston Ring End Gap Inspection

Place the piston ring [A] inside the cylinder (upper

crankcase), using the piston to locate the ring squarely

in place. Set it close to the bottom of the cylinder, where

cylinder wear is low.

Measure the gap [B] between the ends of the ring with a

thickness gauge.

Piston Ring End Gap ...

Subthrottle Sensor Output Voltage Inspection

Measure the output voltage at the subthrottle sensor in

the same way as input voltage inspection, note the following.

Disconnect the subthrottle sensor connector and connect

the setting adapter [A] between these connectors.

Special Tool - Throttle Sensor Setting Adapter: 57001

-1538

...

Engine Vacuum Synchronization Inspection

NOTE

These procedures are explained on the assumption that

the intake and exhaust systems of the engine are in

good condition.

Situate the motorcycle so that it is vertical.

Remove:

Fuel Tank (see Fuel Tank Removal in the Fuel System

(DFI) chapter)

Air Cleaner Housing (see Air Cleaner ...