Special Tool - Hand Tester: 57001-1394

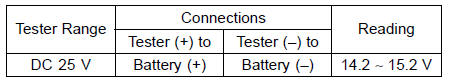

Charging Voltage

If the charging voltage is kept between the values given in the table, the charging system is considered to be working normally.

If the charging voltage is much higher than the values specified in the table, the regulator/rectifier is defective or the regulator/rectifier leads are loose or open.

If the charging voltage does not rise as the engine speed increases, then the regulator/rectifier is defective or the alternator output is insufficient for the loads. Check the alternator and regulator/rectifier to determine which part is defective.

Alternator Rotor Installation

Alternator Rotor Installation Alternator Inspection

Alternator InspectionService Code Reading

The service code(s) is displayed on the LCD by the number

of two digits.

NOTE

The service code of the KIBS and ABS adds “b” at the

left side of the code.

The service code of the ESD adds “E” at the left side of

the code.

When there are a number of problems, all the serv ...

Intake Air Temperature Meter

Intake air temperature meter indicates

temperature of the air in the air

cleaner case.

The “Intake Air” is displayed if the intake

air temperature meter is selected.

A. Intake Air Temperature Meter

B. “Intake Air”

NOTE

The intake air temperature meter

shift to the coolant temp ...

Exploded View

10. US, CA, CAL and AU Models

11. ZX1000JD/KD

G: Apply grease.

L: Apply a non-permanent locking agent.

R: Replacement Parts

S: Follow the specified tightening sequence.

1. US, CA and CAL Models

2. ZX1000J Model

3. ZX1000K Model

4. AU Model

5. Face the large diameter side re ...