There are three types of alternator failures: short, open (wire burned out), or loss in rotor magnetism. A short or open in one of the coil wires will result in either a low output, or no output at all. A loss in rotor magnetism, which may be caused by dropping or hitting the alternator, by leaving it near an electromagnetic field, or just by aging, will result in low output.

Turn the ignition switch to OFF.

Remove the left upper inner fairing (see Upper Inner Fairing Removal in the Frame chapter).

Disconnect the alternator lead connector [A].

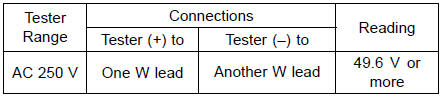

Connect the hand tester as shown in the table 1.

Special Tool - Hand Tester: 57001-1394

Start the engine.

Run it at the rpm given in the table 1.

Note the voltage readings (total 3 measurements).

Table 1 Alternator Output Voltage at 4 000 r/min (rpm)

If the output voltage shows the value in the table, the alternator operates properly. The regulator/rectifier is damaged.

If the output voltage shows a much lower reading than that given in the table, stop the engine and inspect the stator coil resistance.

Stop the engine.

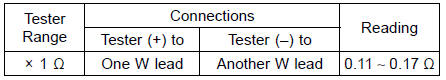

Connect the hand tester as shown in the table 2.

Special Tool - Hand Tester: 57001-1394

Table 2 Stator Coil Resistance at 20°C (68°F)

If there is more resistance than shown in the table, or no hand tester reading (infinity) for any two leads, the stator has an open lead and must be replaced. Much less than this resistance means the stator is shorted, and must be replaced.

Any hand tester reading less than infinity (∞) indicates a short, necessitating stator replacement.

If the stator coil has normal resistance, but the voltage check showed the alternator to be defective; then the rotor magnets have probably weakened, and the rotor must be replaced.

Charging Voltage Inspection

Charging Voltage Inspection Regulator/Rectifier Inspection

Regulator/Rectifier InspectionCam Wear Inspection

Remove the camshafts (see Camshaft Removal).

Measure the height [A] of each cam with a micrometer.

If the cams are worn down past the service limit, replace

the camshaft.

Cam Height

Standard:

Exhaust 35.043 35.157 mm

(1.3796 1.3841 in.)

Intake 38.243 38.357 mm

(1.5056 1.5101 in. ...

Rear Wheel Rotation Sensor Signal Abnormal (Service Code b 44)

Measure the air gap between the rear wheel rotation sensor

and sensor rotor.

Thickness Gauge [A]

Air Gap

Standard: 0.4 1.6 mm (0.02

0.06 in.)

If the measurement is not the standard, check each part

for deformation and looseness and correct accordingly.

If the measurement is the sta ...

S-KTRC Mode Indicator

This indicator shows the selected

S-KTRC mode. For more detailed information

about the S-KTRC mode,

see Sport-Kawasaki TRaction Control

(S-KTRC) section in the How to Ride

the Motorcycle chapter

A. S-KTRC Mode Indicator

NOTE

When the all S-KTRC mode indicators

go off, the battery voltag ...