The compression damping force adjuster and the rebound damping force adjuster are located on top of each front fork leg.

NOTICE

Do not force to turn the rebound and compression damping force adjuster from the fully seated position, or the adjusting mechanism may be damaged.

A. Compression Damping Force Adjuster (COM)

B. Rebound Damping Force Adjuster (TEN)

C. Screwdriver

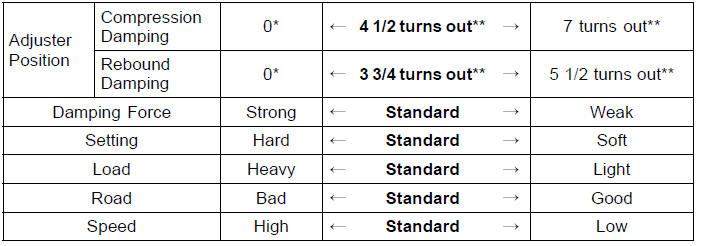

Compression Damping Force Setting and Rebound Damping Force Setting

*: This position is the fully seated position (turned fully clockwise).

**: Out from the fully seated position (turned fully clockwise). This adjustment range may not exactly match the number shown in the table due to small tolerance of production.

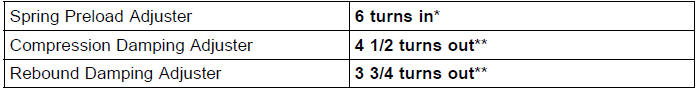

The standard front fork setting positions are as follows:

Standard Setting Position (Front Fork)

*: In from the fully seated position (turned fully counterclockwise) **: Out from the fully seated position (turned fully clockwise)

Spring Preload Adjustment

Spring Preload Adjustment Rear Shock Absorber

Rear Shock AbsorberKeys

This motorcycle has a combination

key, which is used for the ignition

switch, steering lock, seat lock, and

fuel tank cap.

Included with the key is a key number,

which may be stamped on a separate

plate. Record the key number in

the space provided and store the number

in a safe place. If y ...

Cam Wear Inspection

Remove the camshafts (see Camshaft Removal).

Measure the height [A] of each cam with a micrometer.

If the cams are worn down past the service limit, replace

the camshaft.

Cam Height

Standard:

Exhaust 35.043 35.157 mm

(1.3796 1.3841 in.)

Intake 38.243 38.357 mm

(1.5056 1.5101 in. ...

Engine Oil Change

Situate the motorcycle so that it is vertical after warming

up the engine.

Remove the engine oil drain bolt [A] to drain the oil.

The oil in the oil filter can be drained by removing the filter

(see Oil Filter Replacement).

Replace the drain bolt gasket [B] with a new one.

Tighten t ...