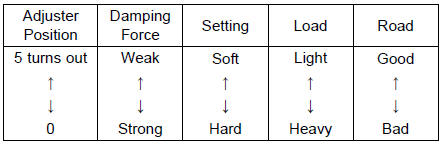

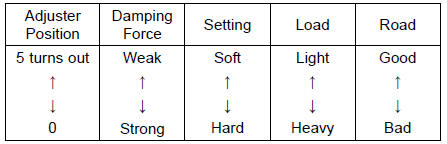

There are two adjustments you can make to the compression damping force.

High Speed Compression Damping Adjuster [A] Low Speed Compression Damping Adjuster [B]

The standard adjuster setting is the 1 3/4 turns out from the fully clockwise position.

High Speed Compression Damping Force Adjustment

NOTE

When turning the high speed compression damping force adjuster (outside), turn the low speed compression damping force adjuster (inside) too. But, the low speed compression damping force (setting position) dose not change.

The standard adjuster setting is the 1 3/4 turns out from the fully clockwise position.

Low Speed Compression Damping Force Adjustment

Rebound Damping Force Adjustment

Rebound Damping Force Adjustment Spring Preload Adjustment

Spring Preload AdjustmentRadiator and Radiator Fan Installation

If the radiator bracket [A] was removed, install it.

Install the radiator fan to the radiator

Tighten the radiator fan mounting bolts.

When installing the pad [B], install it so that the upper end

of the pad aligns with the corner top [C].

When install the pad [D], install it so that the ...

Meter Unit Circuit (ZX1000K Model)

1. Ignition Switch

2. Joint Connector F

3. Stop Watch Button

4. Oil Pressure Switch

5. Crankshaft Sensor

6. Water Temperature Sensor

7. Gear Position Switch

8. Intake Air Temperature Sensor

9. ESD ECU (ZX1000JD/KD)

10. ECU

11. Rear Wheel Rotation Sensor

12. Frame Ground 1

13. Engine ...

General Precautions

Frequent and proper care of your

Kawasaki motorcycle will enhance

its appearance, optimize overall performance,

and extend its useful life.

Covering your motorcycle with a high

quality, breathable motorcycle cover

will help protect its finish from harmful

UV rays, pollutants, and reduce the ...