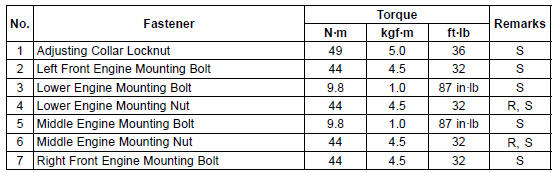

M: Apply molybdenum disulfide grease.

R: Replacement Parts

S: Follow the specified tightening sequence.

Special Tool

Engine Mount Nut Wrench:

57001-1450

Kawasaki Intelligent anti-lock Brake System (KIBS,

For models equipped with KIBS)

KIBS regulates anti-lock braking performance

with more precision during

sports riding compared to a conventional

ABS system.

KIBS is designed to help prevent

the wheels from locking up when the

brakes are applied hard while riding

straight. KIBS automatically regulates

brake force using en ...

IC Igniter Inspection

The IC igniter is built in the ECU [A].

Refer to the following items.

Interlock Operation Inspection (see Interlock Operation

Inspection)

Ignition System Troubleshooting (see Ignition System

section)

ECU Power Supply Inspection (see ECU Power Supply

Inspection in the Fuel System (D ...

Meter Operation Inspection

Check 1-1: Switching Inspection

Turn the ignition switch to ON and check the following.

The all LCD segments [A] appear for 3 seconds.

The warning indicator light (Red LED) [B] goes on for 3

seconds and then goes off in a moment after that goes

off.

The warning indicator light (Yellow LED ...