25. “1T” marked side faces up.

26. “T2” marked side faces up.

27. Hollow mark faces exhaust side.

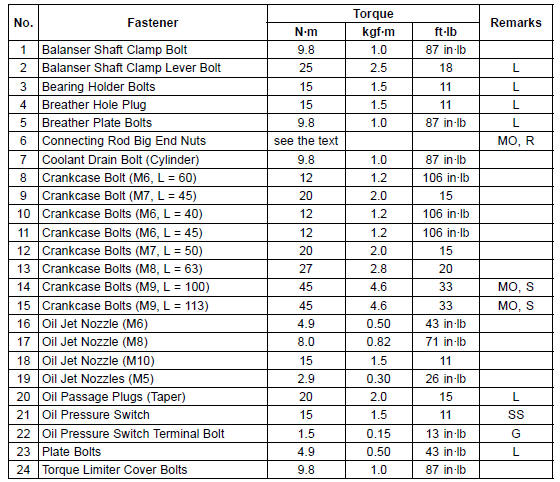

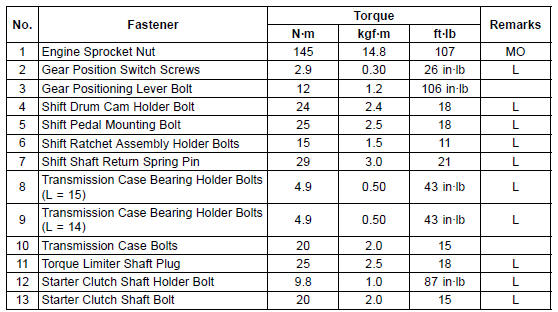

G: Apply grease.

L: Apply a non-permanent locking agent.

LG: Apply liquid gasket.

M: Apply molybdenum disulfide grease.

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1) R: Replacement Parts

S: Follow the specified tightening sequence.

SS: Apply silicone sealant.

WL: Apply soap and water solution or rubber lubricant.

14. Frame No. JKAZXCJ1CA011772 ∼ G: Apply grease.

L: Apply a non-permanent locking agent.

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1) R: Replacement Parts

Specifications

SpecificationsRear Wheel Installation

Apply high-temperature grease to the grease seal lips.

Fit the collars on the both sides of the hub.

Left Side Collar [A]

Right Side Collar [B] (with Flange)

Engage the drive chain with the rear sprocket.

Install the caliper bracket [A] onto the stopper [B] of the

swingarm.

...

DFI Servicing Precautions

There are a number of important precautions that should

be followed servicing the DFI system.

This DFI system is designed to be used with a 12 V sealed

battery as its power source. Do not use any other battery

except for a 12 V sealed battery as a power source.

Do not reverse the battery ...

Radiator Cap Inspection

Remove:

Radiator Cap (see Coolant Change in the Periodic Maintenance

chapter)

Check the condition of the bottom [A] and top [B] valve

seals and valve spring [C].

If any one of them shows visible damage, replace the cap

with a new one.

Install the cap [A] on a cooling system pr ...