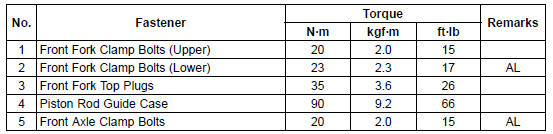

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease.

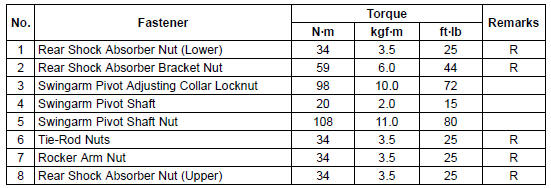

R: Replacement Parts

G: Apply grease.

L: Apply a non-permanent locking agent.

R: Replacement Parts

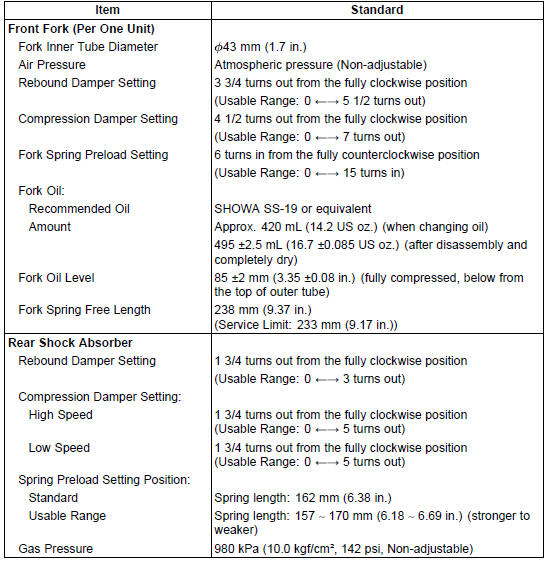

Specifications

Suspension

Suspension Special Tools

Special ToolsThrottle Body Assy Installation

Apply a thin coat of grease to the throttle cable lower ends.

Fit the accelerator cable end [A] and the decelerator cable

end [B] into the throttle pulley.

Install the clamp [C] securely.

Install the throttle body assy holder clamp bolt heads [A]

outside as shown in the figure.

...

Leather, Vinyl, and Rubber

If your motorcycle has leather accessories,

special care must be taken.

Use a leather cleaner/treatment to

clean and care for leather accessories.

Washing leather parts with detergent

and water will damage them, shortening

their life.

Vinyl parts should be washed with the

rest of themo ...

Check 3-1: CAN Communication Line Resistance Inspection

Set the hand tester [A] to the ×1 Ω range and connect it

to the terminal [11] and [12] in the meter unit.

Special Tool - Hand Tester: 57001-1394

CAN Communication Line Resistance (at Meter Unit)

Standard: 122 126 Ω

If the tester reading is not specified, replace the meter ...