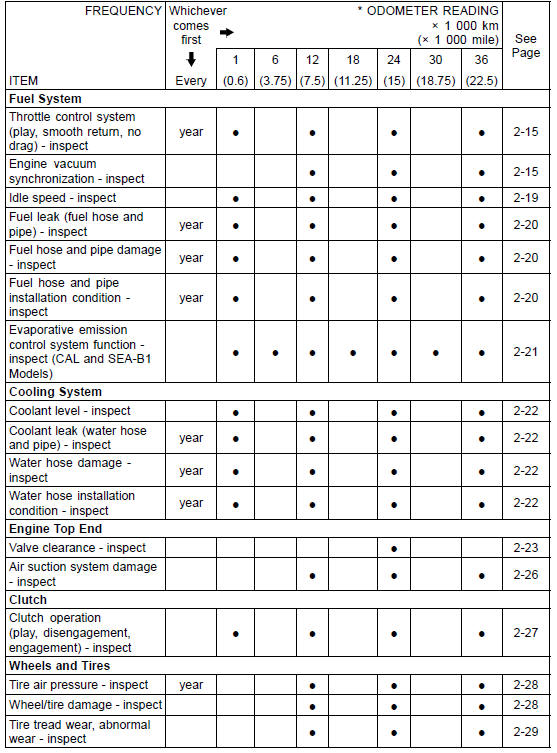

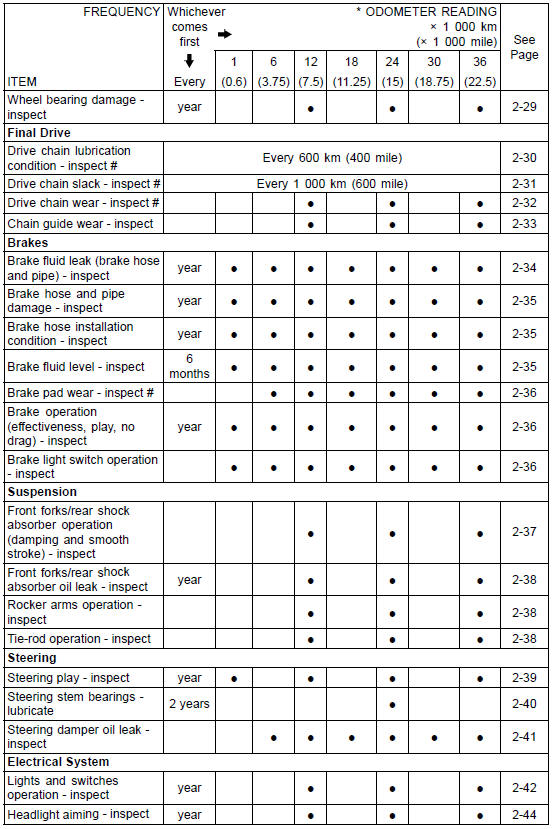

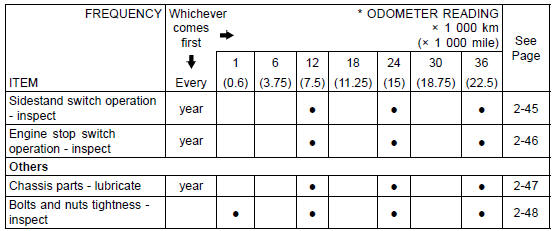

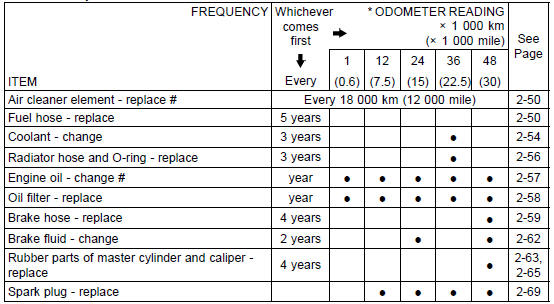

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition. The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

Periodic Replacement Parts

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

Torque and Locking Agent

Torque and Locking AgentKIBS Hydraulic Unit Installation

NOTICE

Brake fluid quickly ruins painted plastic surfaces;

any spilled fluid should be completely washed away

immediately.

Install the KIBS hydraulic unit together with the bracket.

Before installing the brake pipe, check to see that there is

no damage on the threads of the brake pipe joi ...

Sidestand Installation

Replace the sidestand nut [A] with a new one.

Apply grease to the sliding areas [B].

Tighten the sidestand bolt [C] first, and then the sidestand

nut.

Torque - Sidestand Bolt: 44 N·m (4.5 kgf·m, 32 ft·lb)

Sidestand Nut: 29 N·m (3.0 kgf·m, 21 ft·lb)

Install the spring [D] as sh ...

Subthrottle Valve Actuator Input Voltage Inspection

NOTE

Be sure the battery is fully charged.

Turn the ignition switch to OFF.

Disconnect the subthrottle valve actuator connector and

connect the measuring adapter [A] between these connectors

as shown in the figure.

Main Harness [B]

Subthrottle Valve Actuator [C]

Special Tool ...