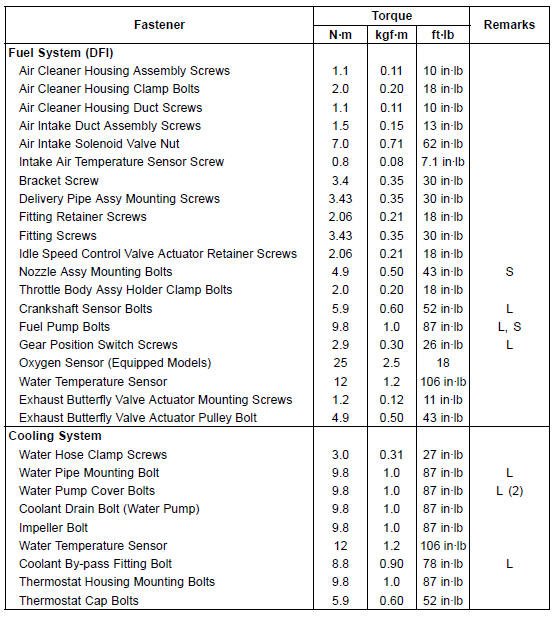

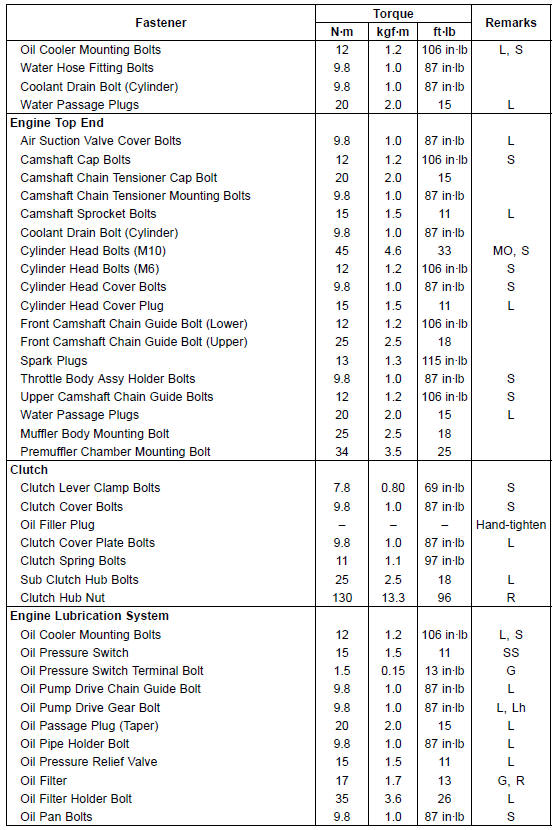

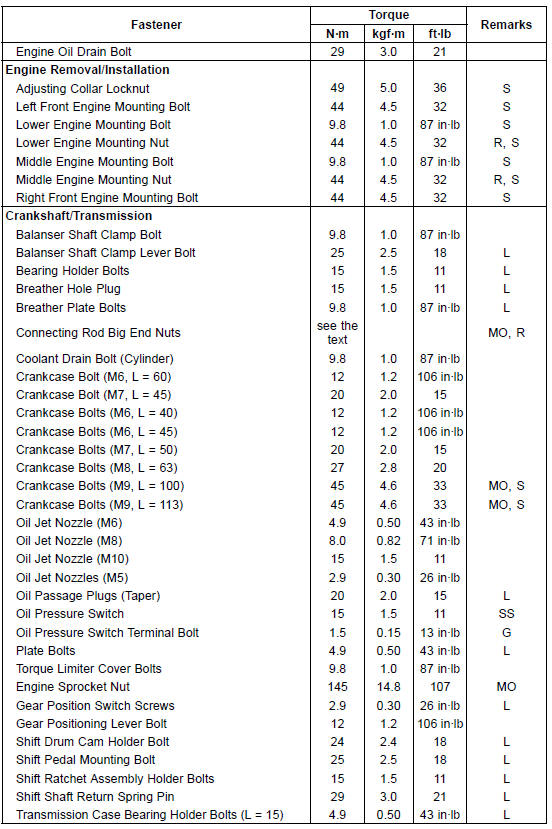

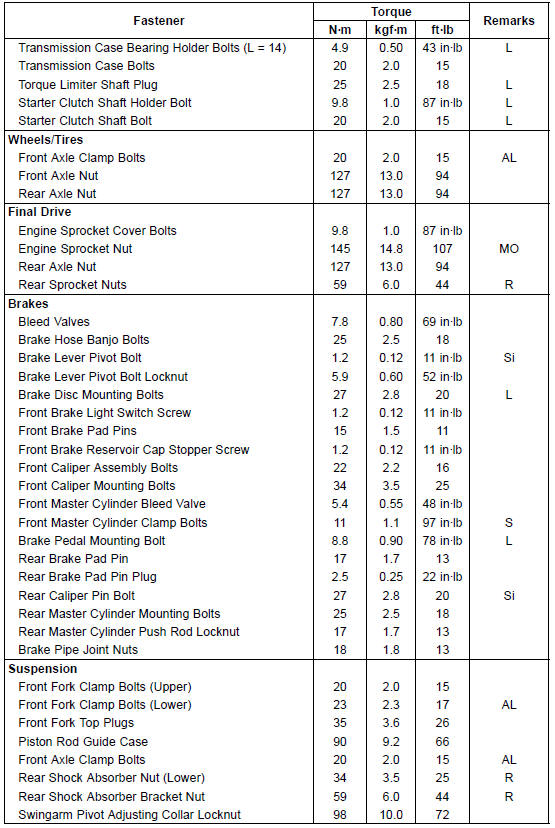

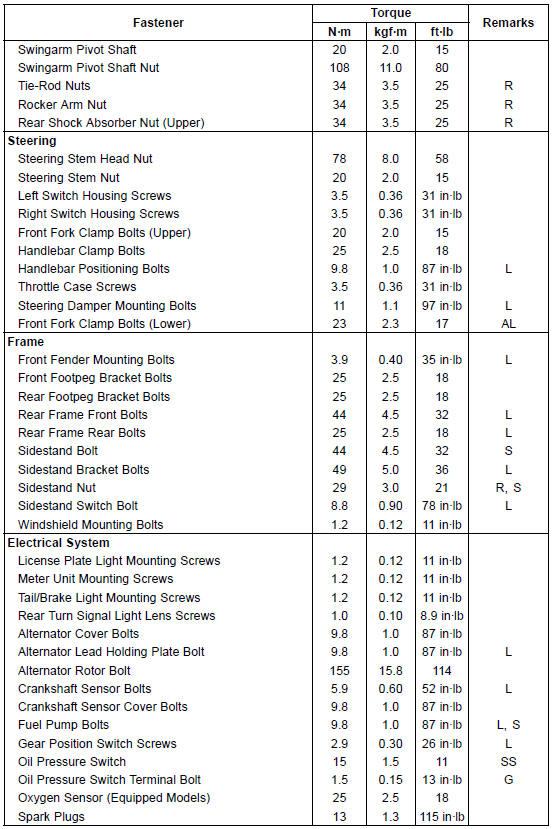

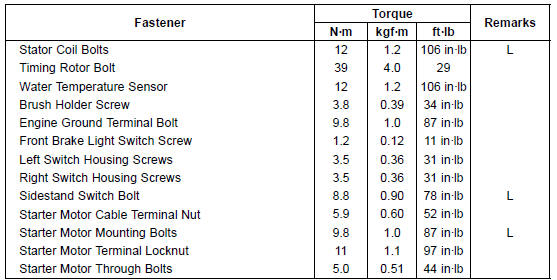

The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean: AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease.

L: Apply a non-permanent locking agent.

Lh: Left-hand Threads

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1)

R: Replacement Parts

S: Follow the specified tightening sequence.

Si: Apply silicone grease (ex. PBC grease).

SS: Apply silicone sealant.

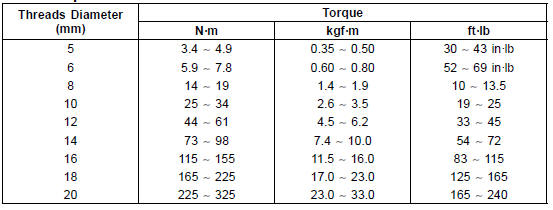

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

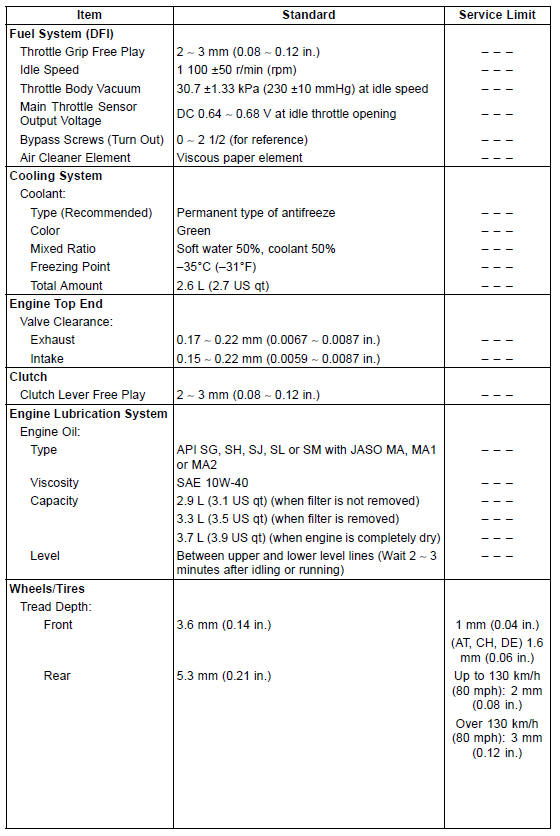

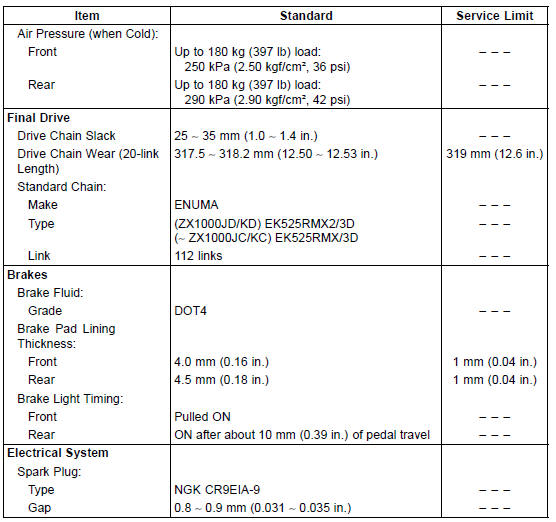

Specifications

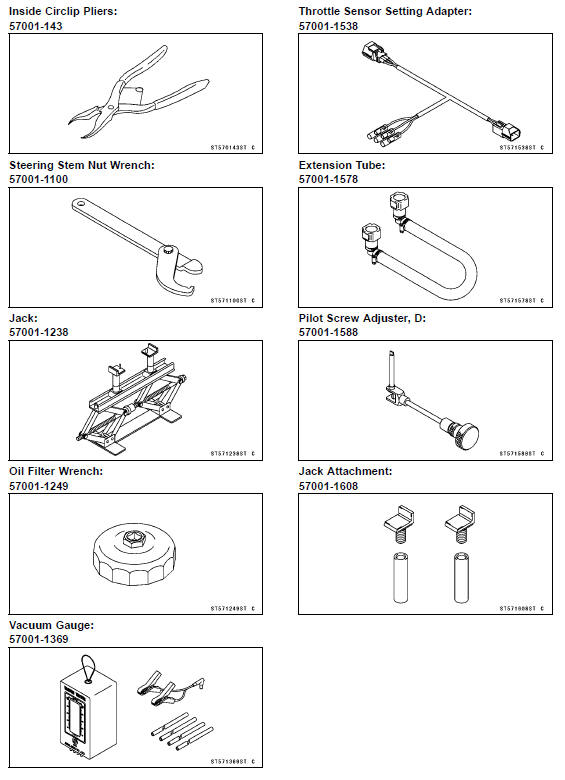

Special Tools

Periodic Maintenance Chart

Periodic Maintenance ChartReplacement Parts

Replacement parts must be KAWASAKI genuine or

recommended by KAWASAKI. Gaskets, O-rings, oil seals,

grease seals, circlips, cotter pins or self-locking nuts must

be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly,

howe ...

Starter Motor Disassembly

Remove the starter motor (see Starter Motor Removal).

Take off the starter motor through bolts [A] and remove

the both end covers [B].

Pull out the armature [A] out of the yoke [B].

NOTE

Do not remove the circlip [C] from the shaft.

Remove the starter motor terminal lock ...

Crankcase Halves Assembly

Install:

Crankshaft (see Crankshaft Installation)

Connecting Rods (see Connecting Rod Installation)

Using a cleaning fluid, clean off any oil or dirt on the mating

surface of the crankcase halves.

Apply liquid gasket to the mating surface of the lower

crankcase half as shown in the fi ...