NOTE

Mark and record the locations of the valve lifters and shims so that they can be reinstalled in their original positions.

a + b – c = d

[a] Present Shim Thickness

[b] Measured Valve Clearance

[c] Specified Valve Clearance (Mean Value = 0.195 mm (Exhaust), 0.185 mm (Intake))

[d] Replace Shim Thickness

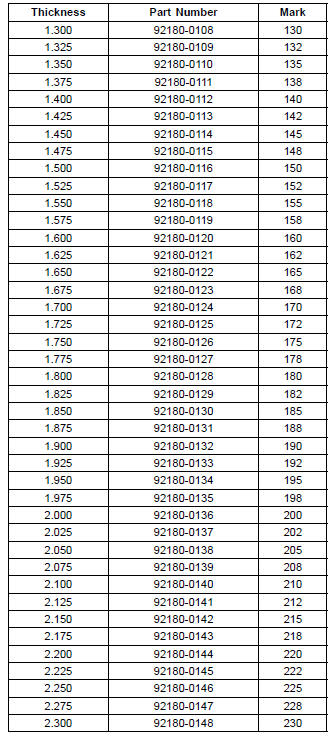

Example (Exhaust): 1.600 + 0.28 – 0.195 = 1.685 mm

Exchange the shim for the 1.675 size shim.

Adjustment Shims

NOTICE

Be sure to remeasure the clearance after selecting a shim. The clearance can be out of the specified range because of the shim tolerance.

If there is no valve clearance, use a shim that is a few sizes smaller, and remeasure the valve clearance.

NOTICE

Do not put shim stock under the shim. This may cause the shim to pop out at high rpm, causing extensive engine damage.

Do not grind the shim. Thismay cause it to fracture, causing extensive engine damage.

Valve Clearance Inspection

Valve Clearance Inspection Air Suction System Damage Inspection

Air Suction System Damage InspectionFront Fork Inspection

Holding the brake lever, pump the

front fork up and down several times

to inspect smooth stroke.

Visually inspect the front fork for oil

leakage, scoring or scratches on the

outer surface of the inner tube.

If any doubt about the front fork, it

should be checked by an authorized

K ...

Cable, Wire, and Hose Routing

1. Clamp (Hold the regulator/rectifier lead. Run the lead inside of the

installation hole.)

2. Clamp (Bend down the clamp, and hold the main harness and the vacuum hose

(equipped

models).)

3. Clamp (Hold the air intake solenoid valve lead (equipped models).)

4. Run the vacuum hose under ...

Wheel Rotation Sensor Air Gap Inspection

Raise the front/rear wheel off the ground (see Front/Rear

Wheel Removal in the Wheels/Tires chapter).

Measure the air gap between the sensor and sensor rotor

at several points by turning the wheel slowly.

Thickness Gauge [A]

Wheel Rotation Sensor Air Gap

Standard:

Front 0.4 1.6 mm ...