1) Overview

This model has an Electronic Steering Damper (ESD) [A]. Unlike conventional manual adjustment method of Kawasaki, damping characteristics are adjusted by the electronic control unit.

2) Purpose

Designed to offer increased stability at high speed without interfering with light and nimble steering at low speed.

3) Advantages

Damping characteristics are properly adjusted by the electronic control unit based on primarily vehicle speed, and additionally acceleration/deceleration.

During public road riding, lighter damping characteristics are selected to preserve the natural nimble handling of this model.

During circuit riding, stiffer damping settings are chosen to enhance stability for better cornering.

Like the public road riding settings, ESD provides the rider with moderate feedback while maintaining natural handling feel. (moderate and natural work fine here) Electronic control is based on speed and acceleration, so at high speeds stability is enhanced.

4) Difference

Change the steering damper damping adjustment method from manual (ZX1000JC/KC) to automatic (Stepper Motor).

Previous Models ( ZX1000JC/KC)

ZX1000JC/KC)

New Models (ZX1000JD/KD)

5) Related Parts

Meter [A] Electronic Steering Damper (ESD) [B]

ESD ECU [A]

FI ECU [B]

Rear Wheel Rotation Sensor [A]

6) Meter

Added an indicator “ESD” warning symbol [A] in the instruments.

The yellow warning indicator light [B] and ESD warning symbol go on whenever there is a malfunction in the ESD system.

At this time, the ESD system maintains the last damping force setting.

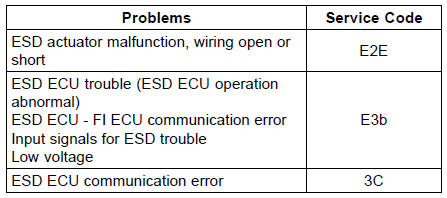

7) Error Display

Only Meter Diagnosis

When both “ESD” warning symbol [A] and yellow warning

indicator light [B] go on , the LCD displays service code

[C] by push the upper button [D] at odometer indication

(see Self-Diagnosis Procedures in the Self-Diagnosis System

chapter).

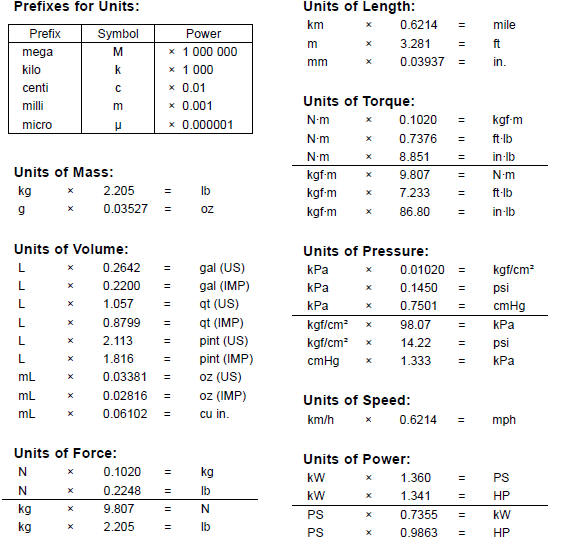

Unit Conversion Table

Related Parts Locations

Related Parts LocationsExhaust Pipe Removal

Remove:

Radiator (see Radiator and Radiator Fan Removal in the

Cooling System chapter)

Exhaust Pipe Clamp Bolt [A] (Loosen)

Remove the exhaust pipe holder nuts [A], and pull out the

exhaust pipe [B] forward from the premuffler chamber.

...

Immobilizer System (Equipped Models)

This motorcycle is equipped with an immobilizer system to protect the

motorcycle from theft. This

system provides a theft proof device by means of matching a code between the

inbuilt key transponder

and ECU. If the code does notmatch, ignition system, injectors, subthrottle

valve actuator an ...

Gear Position Indicator

The gear position indicator shows the

corresponding gear positions where

the transmission is shifted.

For example, when the transmission

is in 6th gear, “6” is displayed.

A. Gear Position Indicator (Normal mode)

NOTE

If the gear position is in the neutral

position, the gear positio ...