NOTE

Do not move the connecting rod and crankshaft during clearance measurement.

Remove the connecting rod big end again, measure each clearance between the bearing insert and crankpin [A] using plastigage (press gauge) [B].

NOTICE

After measurement, replace the connecting rod bolts and nuts.

Connecting Rod Big End Bearing Insert/Crankpin Clearance

Standard: 0.030  0.060 mm

0.060 mm

(0.0012  0.0024 in.)

0.0024 in.)

Service Limit: 0.10 mm (0.0039 in.)

If the clearance is within the standard, no bearing replacement is required.

If the clearance is between 0.061 mm (0.0024 in.) and the service limit (0.10 mm, 0.0039 in.), replace the bearing inserts [A] with inserts painted blue [B]. Check insert/ crankpin clearance with the plastigage. The clearance may exceed the standard slightly, but it must not be less than the minimum in order to avoid bearing seizure.

If the clearance exceeds the service limit, measure the diameter of the crankpins.

Crankpin Diameter

Standard: 34.484  34.500 mm

34.500 mm

(1.3576  1.3583 in.)

1.3583 in.)

Service Limit: 34.47 mm (1.3571 in.)

Crankpin Diameter Marks

None 34.484  34.492 mm (1.3576

34.492 mm (1.3576

1.3580 in.)

34.493

34.493

34.500 mm (1.3580

34.500 mm (1.3580

1.3583 in.)

1.3583 in.)

: Crankpin Diameter Marks (“” or

: Crankpin Diameter Marks (“” or

No Mark)

NOTE

The mark already on the big end should almost coincide with the measurement.

Connecting Rod Big End Inside Diameter Marks

None 37.500  37.508 mm

37.508 mm

(1.4764  1.4767 in.)

1.4767 in.)

37.509

37.509

37.516 mm (1.4767

37.516 mm (1.4767

1.4770 in.)

1.4770 in.)

Big End Cap [A] Connecting Rod [B] Weight Mark, Alphabet [C] Diameter Mark [D] (“” or No Mark)

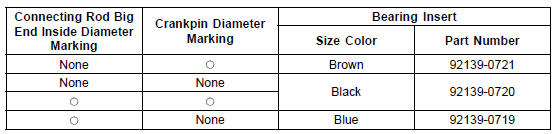

Size Color [B]

Connecting Rod Big End Side Clearance Inspection

Connecting Rod Big End Side Clearance Inspection Crankshaft Side Clearance Inspection

Crankshaft Side Clearance InspectionAlternator Cover Installation

Using a high flash-point solvent, clean off any oil or dirt

that may be on the silicone sealant coating area. Dry

them with a clean cloth.

Apply silicone sealant to the alternator lead grommet and

crankcase halves mating surface [A] on the front and rear

sides of the cover mount.

Sea ...

Cylinder Head Cover Removal

Remove:

Air Suction Valves (see Air Suction Valve Removal)

Throttle Body Assy (see Throttle Body Assy Removal in

the Fuel System (DFI) chapter)

Stick Coils (see Stick Coil Removal in the Electrical System

chapter)

Remove the clamps [A].

Turn up the front side of the heat insulation ...

Fluid Level Inspection

With the brake fluid reservoirs held

horizontal, the brake fluid level must

be kept between the upper and lower

level lines.

A. Front Brake Fluid Reservoir

B. Upper Level Line

C. Lower Level Line

A. Rear Brake Fluid Reservoir

B. Upper Level Line

C. Lower Level Line

If th ...