NOTICE

To minimize vibration, the connecting rods should have the same weight mark.

Big End Cap [A] Connecting Rod [B] Weight Mark, Alphabet [C] Diameter Mark [D] (ŌĆ£ŌĆØ or No Mark)

NOTICE

If the connecting rods, big end bearing inserts, or crankshaft are replaced with new ones, select the bearing insert and check clearance with a plastigage (press gauge) before assembling engine to be sure the correct bearing inserts are installed.

NOTICE

Wrong application of oil and grease could cause bearing damage.

When installing the inserts [A], be careful not to damage the insert surface with the edge of the connecting rod [B] or the cap [C]. One way to install inserts is as follows.

Installation [D] to Cap Installation [E] to Connecting Rod Push [F] Spare Dowel Pin [G] Connecting Rod Bolts [H]

The connecting rod big end is bolted using the ŌĆ£plastic region fastening methodŌĆØ.

This method precisely achieves the needed clamping force without exceeding it unnecessarily, allowing the use of thinner, lighter bolts further decreasing connecting rod weight.

There are two types of the plastic region fastening. One is a bolt length measurement method and other is a rotation angle method. Observe one of the following two, but the bolt length measurement method is preferable because this is a more reliable way to tighten the big end nuts.

NOTICE

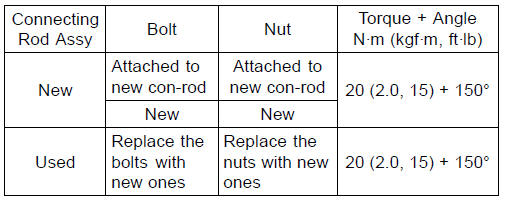

The connecting rod bolts are designed to stretch when tightened. Never reuse the connecting rod bolts. See the table below for correct bolt and nut usage.

NOTICE

Be careful not to overtighten the nuts. The bolts must be positioned on the seating surface correctly to prevent the bolt heads from hitting the crankcase.

(1) Bolt Length Measurement Method

| WARNING Gasoline and low flash-point solvents can be flammable and/or explosive and cause severe burns. Clean the bolts, nuts, and connecting rods in a well-ventilated area, and take care that there are no sparks or flame anywhere near the working area; this includes any appliance with a pilot light. Do not use gasoline or a low flash-point solvent to clean them. |

NOTICE

Immediately dry the bolts and nuts with compressed air after cleaning. Clean and dry the bolts and nuts completely.

If the connecting rod assembly was replaced, use the bolts and nuts attached to the new connecting rod assembly.

Threads [A] of Nuts and Bolts Seating Surfaces [B] of Nuts and Connecting Rods

Connecting Rod [A] Dent here with a punch [B].

Nuts [C] Fit micrometer pins into dents [D].

Bolt Length after tightening ŌĆō Bolt Length before tightening = Bolt Stretch

Connecting Rod Bolt Stretch

Usable Range: 0.24  0.34 mm (0.0094

0.34 mm (0.0094

0.0134 in.)

0.0134 in.)

If the stretch is more than the usable range, the bolt has stretched too much. An overelongated bolt may break in use.

(2) Rotation Angle Method

If you do not have a point micrometer, you may tighten the nuts using the ŌĆ£Rotation Angle MethodŌĆØ.

| WARNING Gasoline and low flash-point solvents can be flammable and/or explosive and cause severe burns. Clean the bolts, nuts, and connecting rods in a well-ventilated area, and take care that there are no sparks or flame anywhere near the working area; this includes any appliance with a pilot light. Do not use gasoline or a low flash-point solvent to clean them. |

NOTICE

Immediately dry the bolts and nuts with compressed air after cleaning. Clean and dry the bolts and nuts completely.

If the connecting rod assembly was replaced, use the bolts and nuts attached to the new connecting rod assembly.

Threads [A] of Nuts and Bolts Seating Surfaces [B] of Nuts and Connecting Rods

Mark [A] the connecting rod big end caps and nuts so that

nuts can be turned 150┬░ [B] properly.

Crankshaft Installation

Crankshaft Installation Crankshaft/Connecting Rod Cleaning

Crankshaft/Connecting Rod CleaningSolenoid Valve Inspection (Service Code b 13, b 14, b 17, b 18)

The solenoid valve is built in the KIBS Hydraulic Unit [A].

Therefore the solenoid valve cannot be checked directly.

Perform the Pre-Diagnosis Inspection 1 and 2 (see Inquiries

to Rider in the Brakes chapter).

If any of these service codes appears even if all checks

are ended, replace t ...

Intake Air Temperature Meter

Intake air temperature meter indicates

temperature of the air in the air

cleaner case.

The ŌĆ£Intake AirŌĆØ is displayed if the intake

air temperature meter is selected.

A. Intake Air Temperature Meter

B. ŌĆ£Intake AirŌĆØ

NOTE

The intake air temperature meter

shift to the coolant temp ...

Coolant Flow Chart

1. Radiator

2. Radiator Fan

3. Water Pump

4. Oil Cooler

5. Oil Cooler Intake Hose

6. Oil Cooler Outlet Hose

7. Cylinder Jacket

8. Cylinder Head Jacket

9. Thermostat Housing

10. Air Bleeder Hose

11. Radiator Cap

12. Radiator Overflow Hose

13. Reserve Tank

14. Reserve Tank Overflow Ho ...