1. Oil Screen

2. Oil Pump

3. Oil Pressure Relief Valve

4. Oil Filter

5. Oil Pipe

6. Oil Cooler

7. Balancer Oil Passage

8. Main Oil Passage

9. Crankshaft Oil Passage

10. Oil Pressure Switch

11. Camshaft Oil Passages

12. Drive Shaft Oil Passage

13. Output Shaft Oil Passage

14. Starter Clutch Oil Passage

15. Blowby Gas (Crankcase → Air Cleaner Housing)

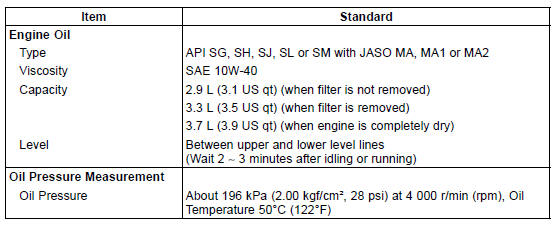

Specifications

Exploded View

Exploded View Special Tools and Sealant

Special Tools and SealantCoolant Deterioration Inspection

Remove the right lower fairing (see Lower Fairing Removal

in the Frame chapter).

Visually inspect the coolant in the reserve tank [A].

If whitish cotton-like wafts are observed, aluminum parts

in the cooling system are corroded. If the coolant is

brown, iron or steel parts are rusting. I ...

Average Mileage

This display mode shows the average

mileage by numerical value

counted from the start of measuring to

present time.

A. Average Mileage

B. “AV km/L”

While the average mileage is displayed,

push the lower button and

hold it in until the average mileage

values resets to “– †...

Inner Tube Inspection

Visually inspect the inner tube [A].

If there is any damage, replace the inner tube. Since

damage to the inner tube damages the oil seal, replace

the oil seal whenever the inner tube is replaced.

NOTICE

If the inner tube is badly bent or creased, replace

it. Excessive bending, followed by ...