NOTE

Do not turn the bolts because the reflector in the headlight comes off.

A. Bolts

A. Left Adjuster

B. Right Adjuster

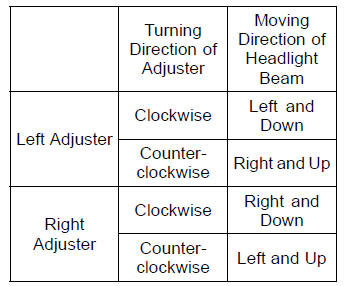

To move the

To move the

headlight beam leftward,

turn the left adjuster clockwise

and turn the right adjuster counterclockwise

same number as the left

adjuster was turned until the beam

points straight ahead.

A. Left Adjuster

B. Right Adjuster

NOTE

On high beam, the brightest points should be slightly below horizontal.

The proper angle is 0.4 degrees below horizontal. This is a 50 mm (2.0 in.) drop at 7.6 m (25 ft) measured from the center of the headlight, with the motorcycle on its wheels and the rider seated.

A. 50 mm (2.0 in.)

B. Center of Brightest Spot

C. 7.6 m (25 ft)

D. Height of Headlight Center

Battery Installation

Battery Installation Fuses

FusesBackups

The ECU takes the following measures to prevent engine damage when the

DFI, ignition, S-KTRC

or immobilizer system parts have troubles.

Note:

(1): D-J Method: When the engine load is light like at idling or low

speed, the ECU determines the

injection quantity by calculating fr ...

Immobilizer Amplifier Replacement

Remove the upper fairing assembly (see Upper Fairing

Assembly Removal in the Frame chapter).

Disconnect the connector [A].

Pull out the immobilizer amplifier [B] together with the rubber

protector [C] from the air intake duct [D].

ECU Replacement

Refer to the ECU Removal/Instal ...

Rear Fender Front Installation

Installation is the reverse of removal. Note the following.

Run the harness, cables and leads correctly (see Cable,

Wire, and Hose Routing section in the Appendix chapter).

When installing the clamp [A] on the rear fender front [B],

install it so that the clamp positions at near the ...