As the tire tread wears down, the tire becomes more susceptible to puncture and failure. An accepted estimate is that 90% of all tire failures occur during the last 10% of tread life (90% worn).

So it is false economy and unsafe to use the tires until they are bald

A. Tire Depth Gauge

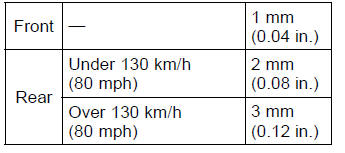

Minimum Tread Depth

NOTE

Have the wheel balance inspected whenever a new tire is installed.

| WARNING Tires that have been punctured and repaired do not have the same capabilities as undamaged tires and can suddenly fail, causing an accident resulting in serious injury or death. Replace damaged tires as soon as possible. To ensure safe handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure. If it is necessary to ride on a repaired tire, do not exceed 100 km/h (60 mph) until the tire is replaced. |

NOTE

When operating on public roadways, keep maximum speed under traffic law limits.

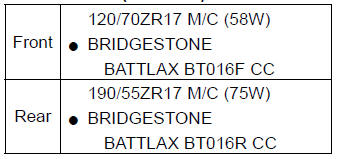

Standard Tire (Tubeless)

| WARNING Some replacement tires may adversely affect handling and cause an accident resulting in serious injury or death. To ensure proper handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure. New tires are slippery and may cause loss of control and injury. A break-in period of 160 km (100 miles) is necessary to establish normal tire traction. During break-in, avoid sudden and maximum braking and acceleration, and hard cornering. |

Payload and Tire Pressure

Payload and Tire Pressure Battery

BatteryOxygen Sensor Removal (Equipped Models)

Remove:

Fuel Tank (see Fuel Tank Removal in the Fuel System

(DFI) chapter)

Right Lower Fairing (see Lower Fairing Removal in the

Frame chapter)

Disconnect the oxygen sensor lead connector [A].

NOTICE

Do not pull strongly, twist, or bend the oxygen sensor

lead. This may cause the wi ...

KIBS Hydraulic Unit Terminal Names

1. Ground: BK

2. CAN Communication Line (High): GY/BL

3. Front Wheel Rotation Sensor Signal Input: Y

4. Power Supply: BR/W

5. KIBS Kawasaki Self-Daignosis System Terminal: P

6. Front and Rear Brake Light Switch Signal: BL/R

7. Unused

8. Front Wheel Rotation Sensor Signal Output: G/Y

9. P ...

Brake Disc Wear Inspection

Measure the thickness of each disc [A] at the point where

it has worn the most.

If the disc has worn past the service limit, replace it.

Measuring Area [B]

Brake Disc Thickness Standard:

Front 5.3 5.7 mm (0.21

0.22 in.)

Rear 4.8 5.2 mm (0.19

0.20 in.)

Service Limit:

Front 5. ...