The battery installed in this motorcycle is a sealed type, so it is not necessary to check the battery electrolyte level or add distilled water.

The sealing strip should not be pulled off once the specified electrolyte has been installed in the battery for initial service.

However, in order to maximize battery life and ensure that it will provide the power needed to start the motorcycle you must properly maintain the battery’s charge. When used regularly, the charging system in the motorcycle helps keep the battery fully charged. If your motorcycle is only used occasionally or for short periods of time, the battery is more likely to discharge.

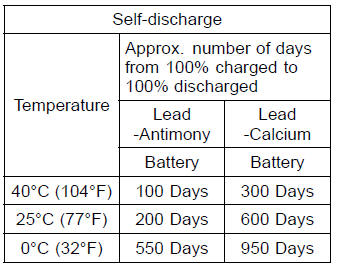

Due to their internal composition, batteries continually self discharge.

The discharge rate depends on the type of battery and ambient temperature.

As temperature rises, so does the discharge rate. Every 15°C (59°F) doubles the rate.

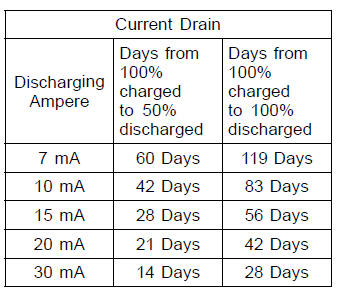

Electrical accessories, such as digital

clocks and computer memory, also

draw current from the battery even

when the key is switched off. Due to

a combination of such “key-off” draws

and hot temperature, a battery can go

from fully charged to completely discharged

in a matter of days.

In extremely cold weather the fluid in an inadequately charged battery can easily freeze, which can crack the case and buckle the plates. A fully charged battery can withstand sub-freezing temperature with no damage.

Tire Wear, Damage

Tire Wear, Damage Battery Sulfation

Battery SulfationRebound Damping Force Adjustment

To adjust the rebound damping force, turn the rebound

damping adjuster [A].

The standard adjuster setting is the 3 3/4 turns out from

the fully clockwise position.

WARNINGIf both adjusters are not adjusted

equally, handling

may be impaired and a hazardous condition may

res ...

Location of parts

Clutch Lever

Left Handlebar Switches

Rebound Damping Force Adjuster

(Front Fork)

Compression damping force adjuster

(Front Fork)

Meter Instruments

Brake Fluid Reservoir (Front)

Right Handlebar Switches

Front Brake Lever

Throttle Grip

Ignition Switch/Steering Lock

Elect ...

Throttle Control System

Check the throttle grip play each day

before riding the motorcycle, and carry

out maintenance and adjustments in

accordance with the Periodic Maintenance

Chart. Adjust it if necessary.

Throttle Grip

The throttle grip controls the butterfly

valves in the throttle body. If the throttle

grip ha ...