Turn Signal Relay [A] Turn Signal Lights [B] 12 V Battery [C]

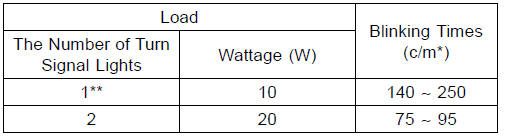

If the lights do not blink as specified, replace the turn signal relay.

Testing Turn Signal Relay

(*): Cycle(s) per minute

(**): Corrected to “one light burned out”.

Turn Signal Light Circuit

1. Ignition Switch

2. Joint Connector A

3. Rear Right Turn Signal Light 12 V 10 W

4. Rear Left Turn Signal Light 12 V 10 W

5. Joint Connector B

6. Battery

7. Main Fuse 30 A

8. Frame Ground

9. Turn Signal Relay

10. Turn Signal Switch

11. Turn Signal Relay Fuse 10 A

12. Fuse Box 1

13. Front Left Turn Signal Light (LED)

14. Front Right Turn Signal Light (LED)

15. Turn Signal Indicator Light (LED)

Rear Turn Signal Light Bulb Replacement

Rear Turn Signal Light Bulb Replacement Air Switching Valve

Air Switching ValveDFI System

1. ECU

2. Battery

3. Vehicle-down Sensor

4. Exhaust Butterfly Valve Actuator

5. Vacuum Chamber (Other than US, CA and CAL Models)

6. Air Intake Valve Actuator (Other than US, CA and CAL Models)

7. Air Intake Valve (Other than US, CA and CAL Models)

8. Air Flow

9. Air Intake Solenoid Valve ...

KIBS Hydraulic Unit Communication Error (Service Code 1b, KIBS Equipped

Models)

KIBS Hydraulic Unit Communication Line Inspection

When the data (for status of KIBS hydraulic unit) is not

sent from the KIBS hydraulic unit to the meter unit and

ECU, the service code 1b is displayed.

The data is sent through the CAN communication line.

The service code 1b is detected with the ...

Subthrottle Sensor Output Voltage Inspection

Measure the output voltage at the subthrottle sensor in

the same way as input voltage inspection, note the following.

Disconnect the subthrottle sensor connector and connect

the setting adapter [A] between these connectors.

Special Tool - Throttle Sensor Setting Adapter: 57001

-1538

...